In today’s fast-paced industrial environment, efficient material handling systems are no longer a luxury—they are a necessity. With rising production demands, stricter quality control, and space limitations in factories, manufacturers need conveyor systems that are reliable, flexible, and tailored to their operational workflows.

Among the many conveyor solutions available in the market, overhead chain conveyor systems have emerged as a preferred choice for industries ranging from automotive and electronics to food processing and metal finishing. By utilizing overhead space and enabling multi-directional travel, these systems dramatically improve floor space usage, reduce manual labor, and increase automation.

But not all overhead conveyors are created equal.

Selecting the right type of overhead chain conveyor for your specific manufacturing process can mean the difference between consistent output and ongoing operational headaches. This article will guide you through the key selection criteria, explore KASIN’s leading conveyor system options, and help you match the right solution to your production needs.

Understanding Industry-Specific Conveyor Demands

Different industries come with different challenges—and therefore different requirements for conveyor systems. For example:

A powder coating plant may need a system that can navigate through multiple turns, temperature zones, and elevation changes.

A food packaging facility, on the other hand, may prioritize hygiene, speed, and spatial efficiency over high-load capabilities.

An automotive component manufacturer might need a heavy-duty conveyor that can carry bulky frames over long production lines, often integrating automated testing or painting stations along the route.

Thus, understanding the unique needs of your industry is the first step in selecting the most suitable overhead chain conveyor system.

The Impact of Conveyor Choice on Manufacturing Efficiency

The conveyor system you select plays a crucial role in shaping the overall efficiency, reliability, and profitability of your manufacturing operations. It impacts several core aspects of production, including:

Production throughput – The right conveyor maximizes the number of units processed within a given time frame.

Material flow consistency – A smooth and uninterrupted material flow minimizes bottlenecks and delays.

Workplace safety – Proper load handling and guided movement reduce the risk of accidents and injuries.

Equipment longevity – A system matched to its load and environment experiences less wear and fewer breakdowns.

Operational costs – Efficient systems require less manual labor, experience fewer stoppages, and reduce energy consumption.

On the other hand, an ill-fitting conveyor system can lead to frequent downtime, inefficient space utilization, and even costly equipment failures due to stress overload or poor route planning. Misaligned systems can also jeopardize worker safety and interrupt synchronized production flows. That’s why choosing the right conveyor system isn’t just about moving products from one place to another—it’s about optimizing the entire production ecosystem.

Key Selection Criteria for Overhead Chain Conveyors

To make an informed decision, consider the following factors when evaluating your conveyor system options:

1. Load Capacity

The maximum weight of the items being transported is perhaps the most important criterion. KASIN offers multiple models:

ETC-5000: A standard chain conveyor system designed for general-purpose loads up to 35 kg per span.

ETC-5000-Plus: A heavy-duty version capable of handling up to 50 kg per span and withstanding high pull forces (up to 3000 kgf).

Four Wheel Bi-planar systems: Specifically engineered for medium loads (up to 150 kg) including the weight of hangers, making them suitable for balanced load transportation over long distances.

Key takeaway: Match your product weight to the appropriate model to ensure structural safety and long-term performance.

2. Route Complexity and Elevation Changes

Are there multiple bends in your layout? Do the materials need to travel up and down elevation gradients, such as from a pretreatment booth to a drying oven?

For multi-turn routes and complex production flows, the ETC Series is an ideal choice. It offers extensive flexibility, with the ability to make any turn in horizontal and vertical planes.

The Four Wheel Bi-planar type offers less flexibility for sharp turns, but is more stable and efficient for very long and linear or gently curved layouts.

Recommendation: For intricate layouts with multiple zones and limited clearance, the ETC series provides unmatched adaptability.

3. Operating Temperature

Temperature resistance is crucial for industries involving heat treatment, powder coating, drying, and forging.

If your process includes high-temperature tunnels, ovens, or furnaces, selecting a chain system with high-temperature tolerance is essential to avoid deformation and failure.

4. Space Optimization

One of the biggest advantages of overhead conveyors is the ability to utilize ceiling space instead of occupying valuable floor area.

Both the ETC series and Four Wheel Bi-planar systems are excellent choices for facilities with space constraints.

These systems support long horizontal spans and multiple levels of movement, making them ideal for multi-step or in-line production processes.

Pro tip: Map out your available ceiling height and floor-to-ceiling clearance to determine which system best fits your facility’s architecture.

KASIN’s Overhead Conveyor System Options

With decades of engineering experience and a wide installation base, KASIN Industries offers two core overhead conveyor systems to meet varying production demands:

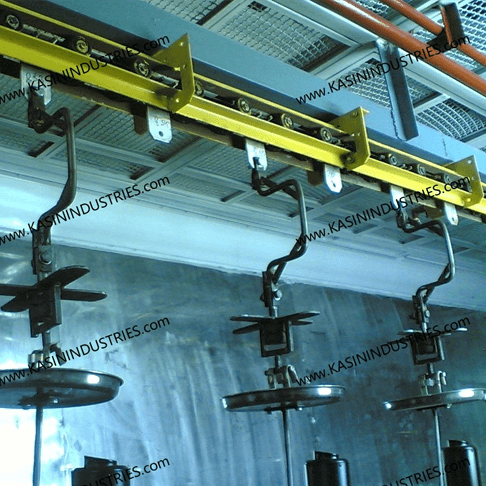

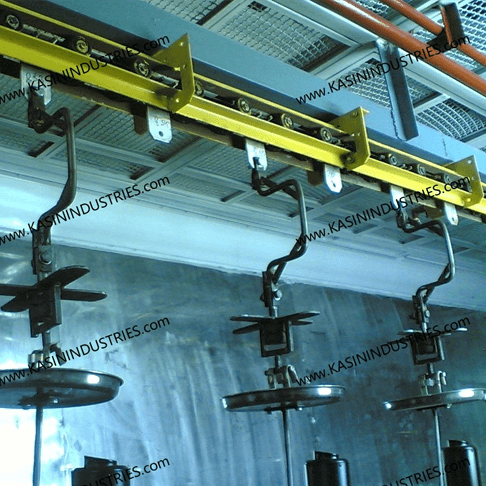

ETC Series Conveyor Chains

KASIN’s ETC Series is known for its modularity, directional flexibility, and load endurance. Designed for highly customized production environments, this system is capable of:

Making tight or wide turns in both horizontal and vertical directions

Withstanding high-temperature environments (up to 400°C for heavy-duty version)

Supporting automated workflows with VFD speed control

Offering suspension spacing flexibility, using the format: 150 + (150 × N) mm

Materials: Manufactured from 16# medium-carbon steel and A3 steel, ensuring strength and wear resistance.

Ideal for: Forging plants, powder coating lines, automotive parts handling, appliance painting, and more.

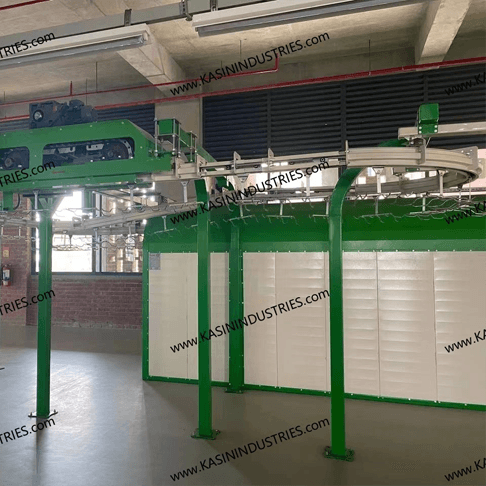

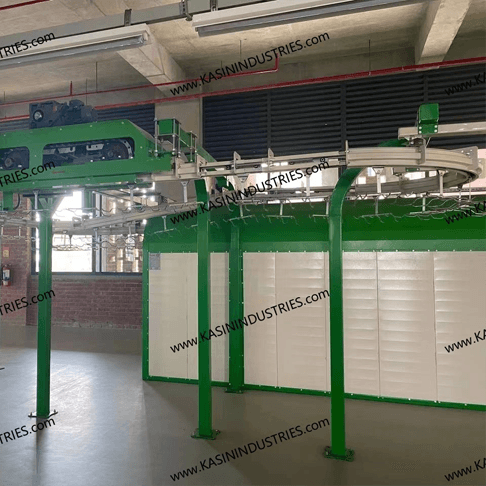

Four Wheel Bi-planar Type Conveyor

This model uses alternate load and transmission links guided precisely along the track. It features:

Balanced load movement due to bi-planar wheel alignment

Maximum hanger/load weight of 150 kg

Best suited for very long layouts, especially in linear or gently curved routes

Moderate flexibility (not suitable for sharp turns)

Applications include: Drying lines, oven systems, WIP material movement, and departments with space constraints.

Industries Served: Food and beverage, automotive, electronics, ceramics, leather, and packaging.

Matching Application Scenarios

Choosing the right system isn't just about technical specs—it’s about matching the system to your production environment and workflow requirements. Below is a breakdown of how different industries can benefit from the right KASIN conveyor system:

Industry | Key Process | Recommended System |

Metal Coating & Powder Coating | High-temp, multi-zone layout | ETC-5000-Plus |

Food Packaging | Light-to-medium loads, spatial constraints | Four Wheel Bi-planar |

Automotive Component Manufacturing | Medium-heavy parts, high-throughput lines | ETC Series or Bi-planar, based on layout |

Electronics Assembly | Clean transfer of lightweight components | ETC-5000 |

Furniture & Appliance Painting | Consistent oven travel, drying & cooling | Bi-planar |

Glass & Ceramics | Fragile handling, smooth movement | ETC Series |

Pharmaceuticals | From washing to packaging zones | ETC Series |

Conclusion: Choosing the Right System Means More Than Just Moving Parts

When it comes to overhead chain conveyors, the right choice brings lasting benefits:

Increased production efficiency

Improved product quality

Optimized floor space

Lower operational and labor costs

Reduced maintenance frequency

KASIN is more than a conveyor manufacturer—it’s a solution partner that offers engineering consultation, customized layout design, and after-sales support tailored to your factory’s unique needs.

Whether you're building a new plant, upgrading a manual line, or adding automation to an existing system, KASIN’s ETC Series and Four Wheel Bi-planar Type conveyor systems offer a flexible and reliable foundation for continuous manufacturing excellence.