In today’s highly competitive manufacturing environment, efficiency is everything. From just-in-time production to 24/7 operations, companies must streamline every process to remain profitable and competitive. One critical bottleneck that often arises in automated factories is material handling—the movement of raw materials, semi-finished goods, and final products between workstations.

Traditional ground-level conveyors and manual material handling methods are not only labor-intensive but also consume valuable floor space. They can disrupt production flow, limit layout flexibility, and slow down cycle times. Enter the overhead chain conveyor system—a proven solution to these challenges.

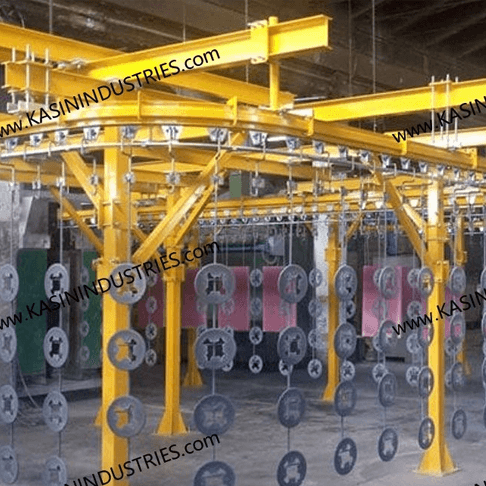

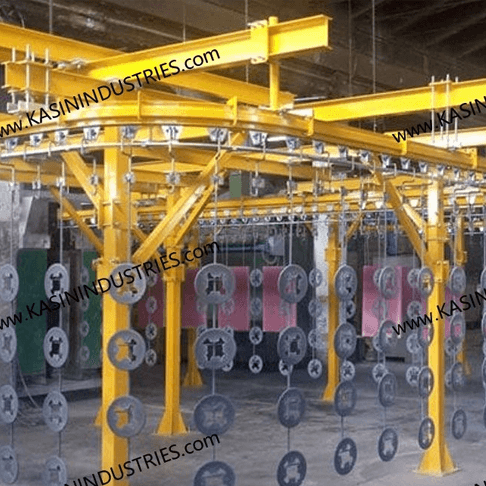

Overhead chain conveyors, particularly the systems offered by Kasin Industries (Shanghai) Co., Ltd., help manufacturers utilize unused vertical space, reduce reliance on manual labor, and automate complex routing requirements. These systems are pivotal in improving workflow efficiency, reducing delays, and enabling continuous operations across diverse industries.

What Are Overhead Chain Conveyors?

An overhead chain conveyor is a mechanical material handling system suspended from the ceiling or an elevated structure, designed to move products or components across predefined routes within a production facility. These systems are powered by continuous chain loops that run inside enclosed or open tracks. Attached to the chains are trolleys, hangers, or carriers that support the movement of goods.

Unlike traditional floor conveyors, overhead chain conveyors leverage vertical space, allowing the ground area to remain uncluttered for other essential operations. This design is especially valuable in space-constrained environments where floor congestion can impact productivity and safety.

Basic Components:

Component | Description |

Drive Unit | Powers the conveyor and regulates chain movement. |

Chain Loop | The core mechanical element that pulls loads along the route. |

Trolleys / Hangers | Hold and transport items across workstations. |

Guide Tracks | Enclosed or open channels that support the chain and guide movement. |

Control Panel / VFD | Automates speed and operation modes, often integrated with PLC systems. |

These conveyors can operate in either continuous or intermittent motion, depending on the application's need. They are capable of navigating horizontal and vertical curves, which allows manufacturers to route materials around equipment, across departments, or through multiple processing zones—all without interrupting other workflows.

Overhead chain conveyors are ideal for complex, multi-step production environments, such as automotive assembly lines, powder coating facilities, and industrial ovens. The systems’ modularity and flexibility also make them adaptable to future expansions or layout changes.

For example, KASIN Industries’ ETC Series is engineered to manage heavy loads, long travel distances, and high-temperature work zones, making it an optimal solution for manufacturers seeking durable, integrated conveyor solutions.

Workflow Optimization Benefits of Overhead Chain Conveyors

Efficiency is the cornerstone of any modern manufacturing facility, and the layout of your material handling system plays a decisive role in achieving it. Overhead chain conveyors offer a transformative solution by reshaping how materials move through your production space. Below are three core workflow advantages that demonstrate why overhead systems—like those from Kasin Industries—are essential for high-performance production lines.

1. Utilize Overhead Space to Free Floor Areas

One of the most immediate benefits of overhead chain conveyors is the ability to clear the floor of bulky transport equipment. By shifting material movement to the ceiling level, manufacturers can reclaim valuable ground space for more productive uses such as:

This change not only boosts layout flexibility but also significantly enhances workplace safety and visual organization.

Comparative Table: Floor vs. Overhead Conveying

Feature | Ground Conveyor | Overhead Chain Conveyor |

Floor Space Required | High | Low |

Material Flow Disruption | Frequent | Minimal |

Safety Hazard (trip/collision) | Higher | Lower |

Kasin’s ETC Series exemplifies this advantage. Its high-strength steel chains and modular suspension framework allow factories to run dual-level workflows—leveraging vertical space for increased throughput without sacrificing operational safety.

2. Seamless End-to-End Integration

Overhead chain conveyors offer unmatched process continuity. A properly designed system integrates all stages of the production flow—starting from raw material input to midline operations like:

Cleaning

Drying

Painting

Baking

Cooling

Quality testing

Final packaging

Instead of depending on manual transport or disjointed transfer points, materials move smoothly across stations via overhead carriers. This uninterrupted flow minimizes idle time, reduces handling errors, and supports Just-in-Time (JIT) and Lean Manufacturing principles.

Moreover, overhead systems can incorporate buffer zones between stations. These act as dynamic queues that hold in-process goods temporarily without interrupting upstream or downstream activities—resulting in a balanced and continuous production rhythm.

3. Multi-Station Synchronization

In complex manufacturing operations, different production stages—such as stamping, welding, pre-treatment, coating, and final assembly—must operate in unison. Delays at any point can snowball into significant bottlenecks and inventory backlogs.

Overhead chain conveyors enable synchronized delivery across all departments by ensuring that materials arrive precisely when and where they are needed. This synchronization helps:

Eliminate inter-department transport delays

Maintain consistent production timing

Reduce work-in-progress (WIP) accumulation

Improve scheduling transparency and accountability

Kasin’s ETC series is especially well-suited for such environments. Designed with an allowable pull force of up to 3000 kgf and temperature resistance from 250°C to 400°C, it performs reliably in extreme conditions—whether inside industrial ovens, furnaces, or chemical pre-treatment lines.

Case Study: KASIN ETC Series

The ETC Series by Kasin Industries exemplifies how overhead chain conveyors improve efficiency on complex layouts.

Technical Highlights:

Parameter | ETC-5000 (Standard) | ETC-5000 Plus (Heavy Duty) |

Suspension Spacing (mm) | 150 + (150 × N) | 150 + (150 × N) |

Chain Weight (kg/m) | 4.2 | 5.3 |

Max Load per Suspension | 35 kg | 50 kg |

Pull Force Allowed (kgf) | 3000 | 3000 |

Working Temp (°C) | ≤250 | ≤400 |

These features allow ETC systems to:

Navigate obstacles and long travel distances

Handle heavy and heat-sensitive workpieces

Automate multi-step workflows such as drying, painting, curing, and inspection

With robust customization options and precise engineering, Kasin systems support industries from automotive and metal fabrication to food, pharmaceuticals, and consumer goods.

Application Versatility: From Steel to Soap

Here are just a few applications of Kasin overhead chain conveyors:

Industry | Application Example |

Automotive | Engine parts, bumpers, chassis handling in painting lines |

Household Appliances | Oven-running refrigerator panels and door assemblies |

Powder Coating & Metal Work | Parts baking & curing workflows |

LPG Cylinder Production | Empty-fill-fill-test-cooling loops |

Food & Beverage | Tin and bottle handling in high-throughput systems |

Textile & Leather | Garment/skin friction drying and transport |

Pharmaceutical | Sterile item handling post-packaging |

Conclusion

As manufacturers aim for smarter, faster, and more efficient operations, overhead chain conveyors stand out as transformative assets. They elevate material handling to the next level—optimizing space, synchronizing workflow across stations, and integrating every stage of production into a continuous, lean system.

Kasin Industries (Shanghai) Co., Ltd. is at the forefront of this transformation. Their innovative ETC series and Four Wheel Bi-planar conveyors combine industry expertise, robust engineering, and customizable design to empower businesses in automotive, metal fabrication, food & beverage, pharmaceuticals, and beyond.

If improving throughput, saving space, and automating complex workflows are top priorities for your production line, consider Kasin’s overhead chain conveyor solutions. Reach out to their team or visit www.kasinindustries.com to start designing the future of your factory.