In the complex ecosystem of industrial machinery, every component plays a vital role in keeping operations running smoothly. While motors, gears, and belts often steal the spotlight, there’s one underrated workhorse that deserves more recognition: the chain coupling—a component that can be the difference between uninterrupted productivity and costly, unexpected downtime.

Whether you’re maintaining a conveyor line in a manufacturing plant, optimizing a pump system in a refinery, or upgrading a mixer in a processing facility, understanding chain couplings is key to minimizing downtime, boosting efficiency, and extending the lifespan of your equipment. Let’s dive into everything you need to know about this critical power transmission component.

What Is a Chain Coupling, Exactly?

A chain coupling is a type of flexible coupling designed to connect two rotating shafts and transmit torque between them—even when the shafts have slight misalignments. Unlike rigid couplings that demand near-perfect alignment, chain couplings accommodate angular, parallel, and axial misalignments, making them a versatile choice for a wide range of industrial applications.

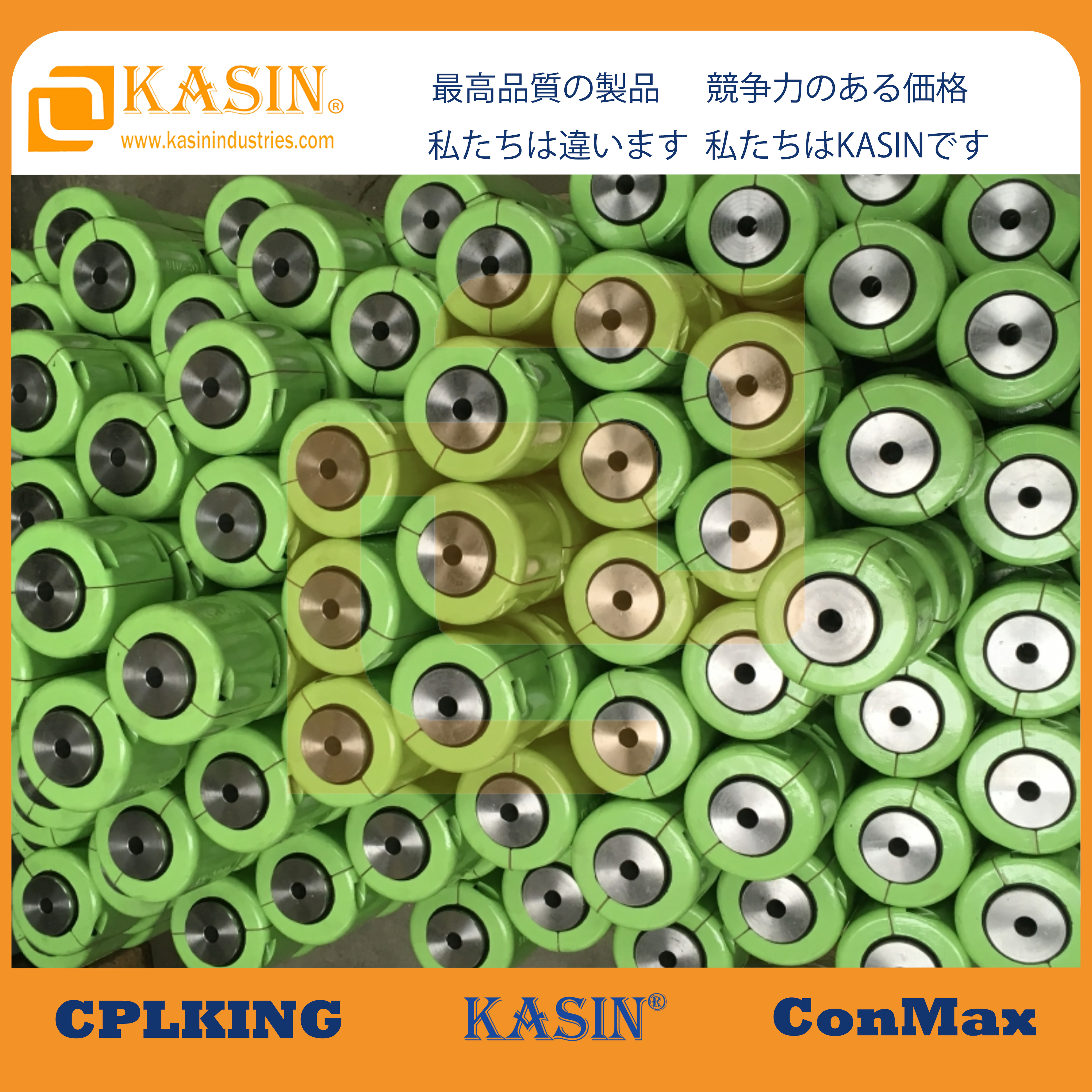

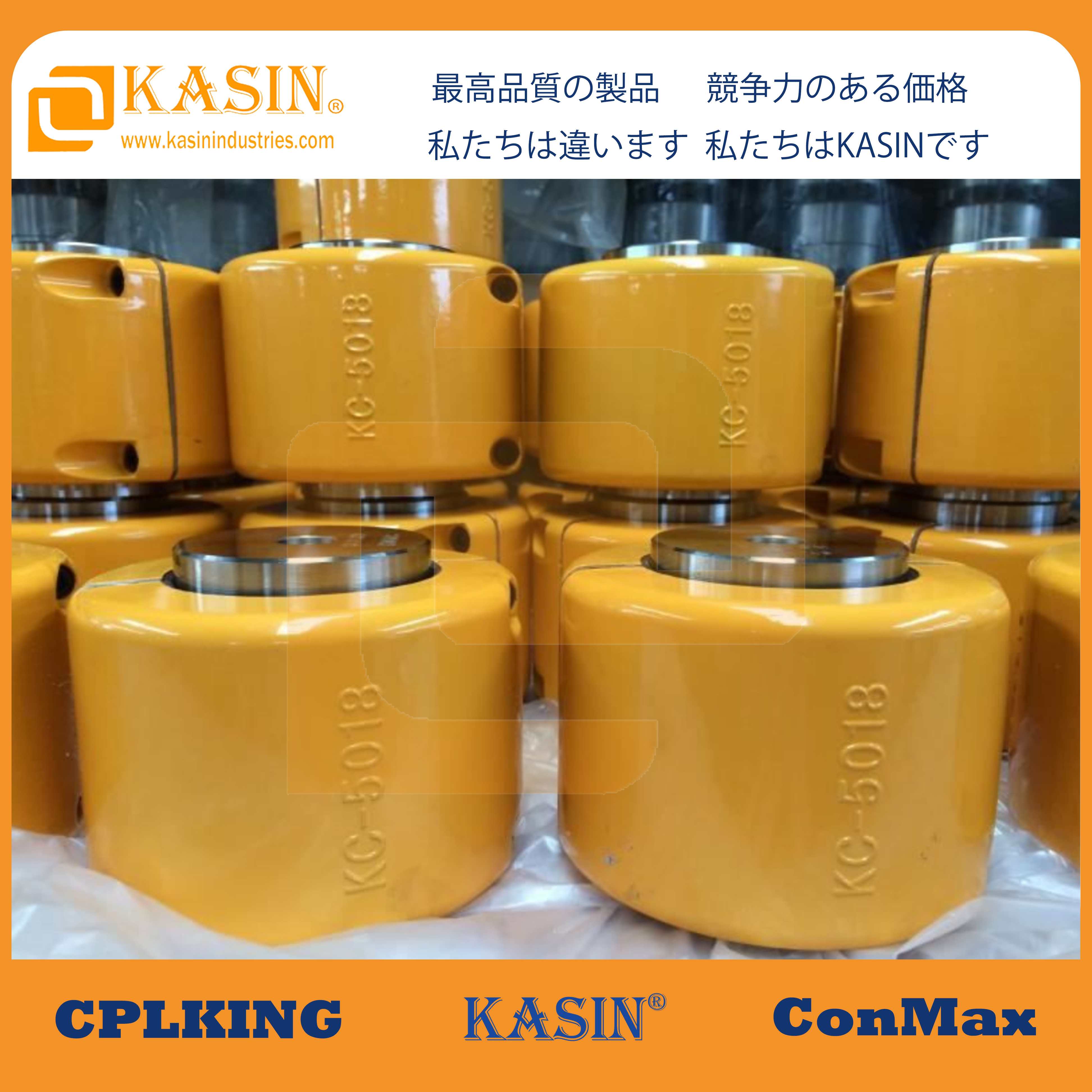

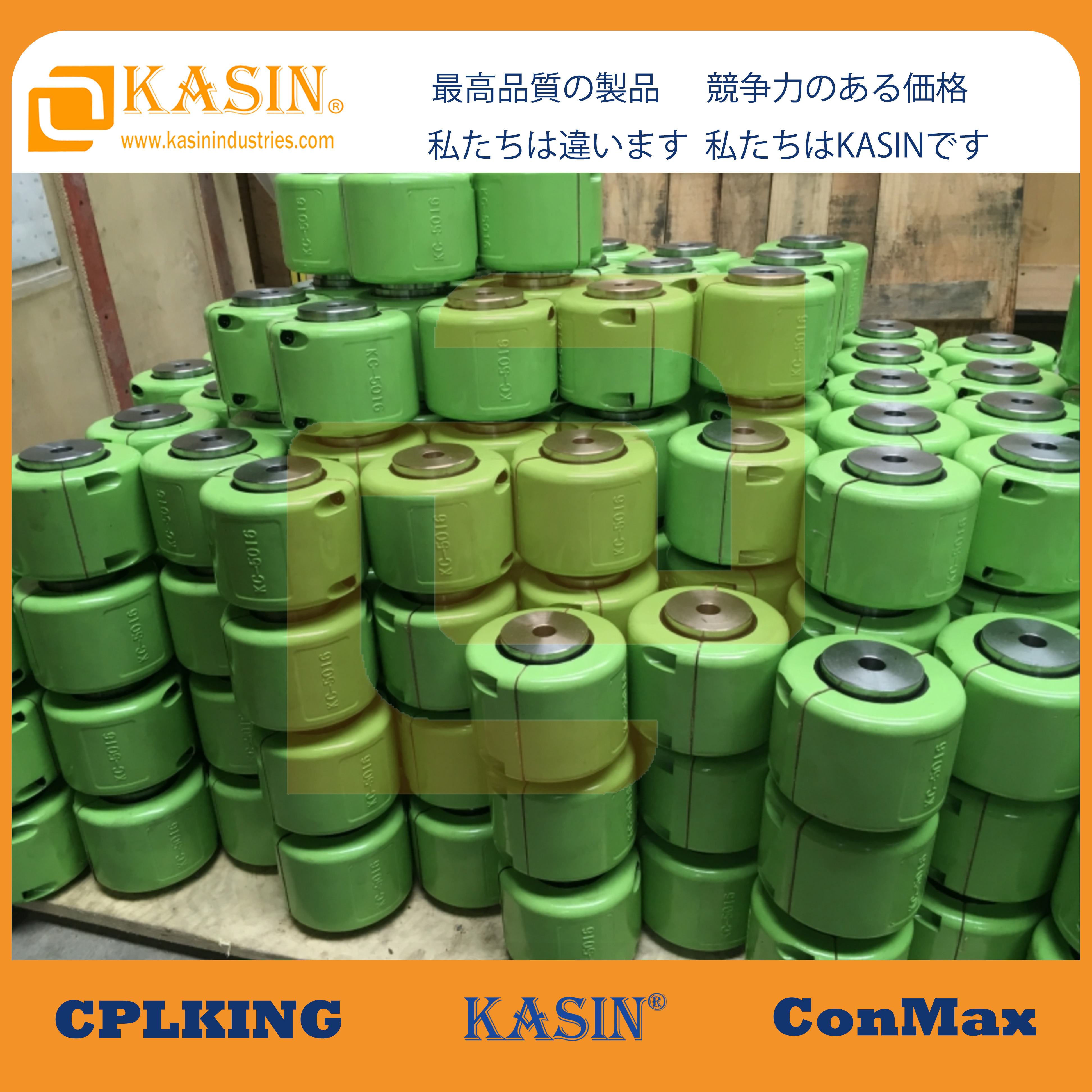

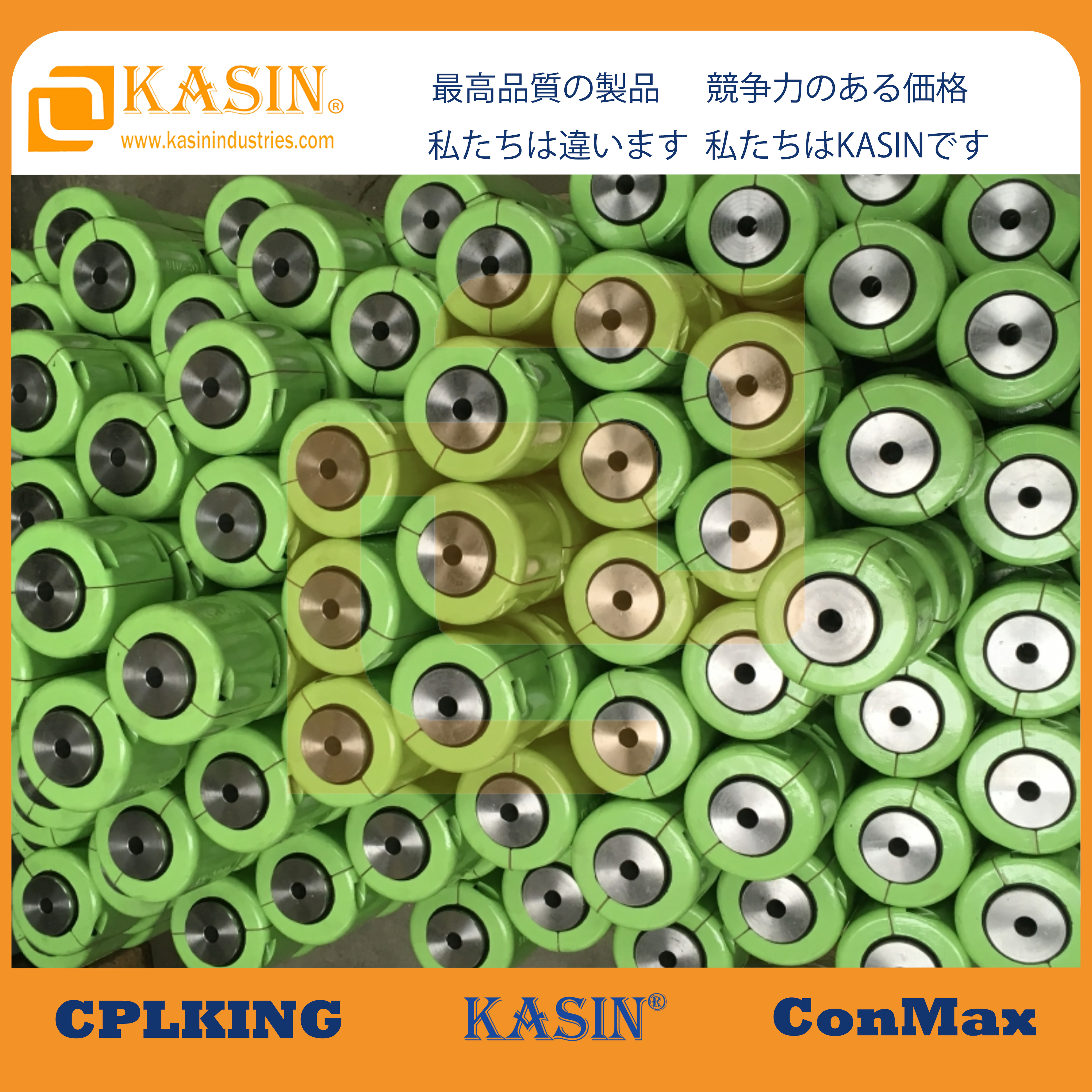

At its core, a standard chain coupling consists of three key parts:

• Two identical sprockets: Attached to the ends of the two shafts that need to be connected.

• A roller chain: Wrapped around both sprockets, acting as the link that transfers torque from one shaft to the other.

• A protective cover (optional but recommended): Shields the sprockets and chain from dust, debris, and accidental contact, while also retaining lubricant to reduce wear.

How Does a Chain Coupling Work?

The working principle of a chain coupling is elegantly simple. When the driving shaft rotates, it turns the connected sprocket, which in turn moves the roller chain. The chain then drives the sprocket on the driven shaft, transferring rotational power seamlessly.

The flexibility of the roller chain is what sets this coupling apart. It allows for small amounts of misalignment between shafts—a common issue in industrial settings due to thermal expansion, vibration, or minor installation variations—without causing excessive stress on the coupling or the connected machinery. This flexibility directly cuts down on premature component failure, one of the top causes of unplanned downtime.

Key Benefits of Chain Couplings for Industrial Applications

Why choose a chain coupling over other coupling types like jaw, gear, or diaphragm couplings? Here are the top advantages that make it a staple in industrial power transmission:

1. High Torque Capacity

Chain couplings are built to handle heavy loads. Constructed from high-strength steel alloys, they excel in high-torque applications such as mining equipment, heavy-duty conveyors, and industrial compressors.

2. Cost-Effective & Easy to Maintain

Compared to precision-engineered gear couplings, chain couplings are more budget-friendly to manufacture and replace. Maintenance is straightforward too—simply lubricate the chain regularly and inspect for wear, and replace the chain or sprockets as needed without disassembling the entire shaft system. This reduces both maintenance costs and equipment downtime.

3. Accommodates Misalignment

As mentioned earlier, their ability to tolerate angular, parallel, and axial misalignment prevents premature failure of both the coupling and the connected machinery, reducing unplanned downtime.

4. Wide Range of Sizes & Customizations

Chain couplings are available in standard sizes to fit most industrial shaft diameters. For unique applications, custom sprocket sizes, corrosion-resistant coatings, or specialized chain materials (e.g., stainless steel for food or chemical processing) can be tailored to meet specific requirements.

Common Applications of Chain Couplings

You’ll find chain couplings hard at work in almost every heavy industry, including:

• Manufacturing: Conveyor systems, packaging machinery, and assembly line equipment

• Oil & Gas: Pumps, compressors, and drilling rig components

• Agriculture: Tractor attachments, grain elevators, and irrigation systems

• Construction: Concrete mixers, crane hoists, and pile drivers

• Food Processing: Stainless steel chain couplings for washdown environments

How to Select the Right Chain Coupling for Your Equipment

Choosing the correct chain coupling isn’t a one-size-fits-all process. Here are three critical factors to consider:

1. Torque Requirement: Calculate the maximum torque your machinery will generate, and select a coupling with a torque rating that exceeds this value to ensure reliability.

2. Shaft Misalignment: Measure the expected misalignment between your driving and driven shafts—chain couplings typically handle up to 1.5° of angular misalignment and 0.25 mm of parallel misalignment.

3. Operating Environment: If your equipment operates in harsh conditions (e.g., high humidity, corrosive chemicals, or extreme temperatures), opt for couplings with protective covers and corrosion-resistant materials.

Final Thoughts: Don’t Overlook This Industrial Workhorse

Chain couplings may not be the most glamorous component in your machinery, but they are undoubtedly one of the most essential. Their durability, versatility, and cost-effectiveness make them a go-to solution for engineers and maintenance teams looking to keep industrial operations running smoothly—and downtime to a minimum.

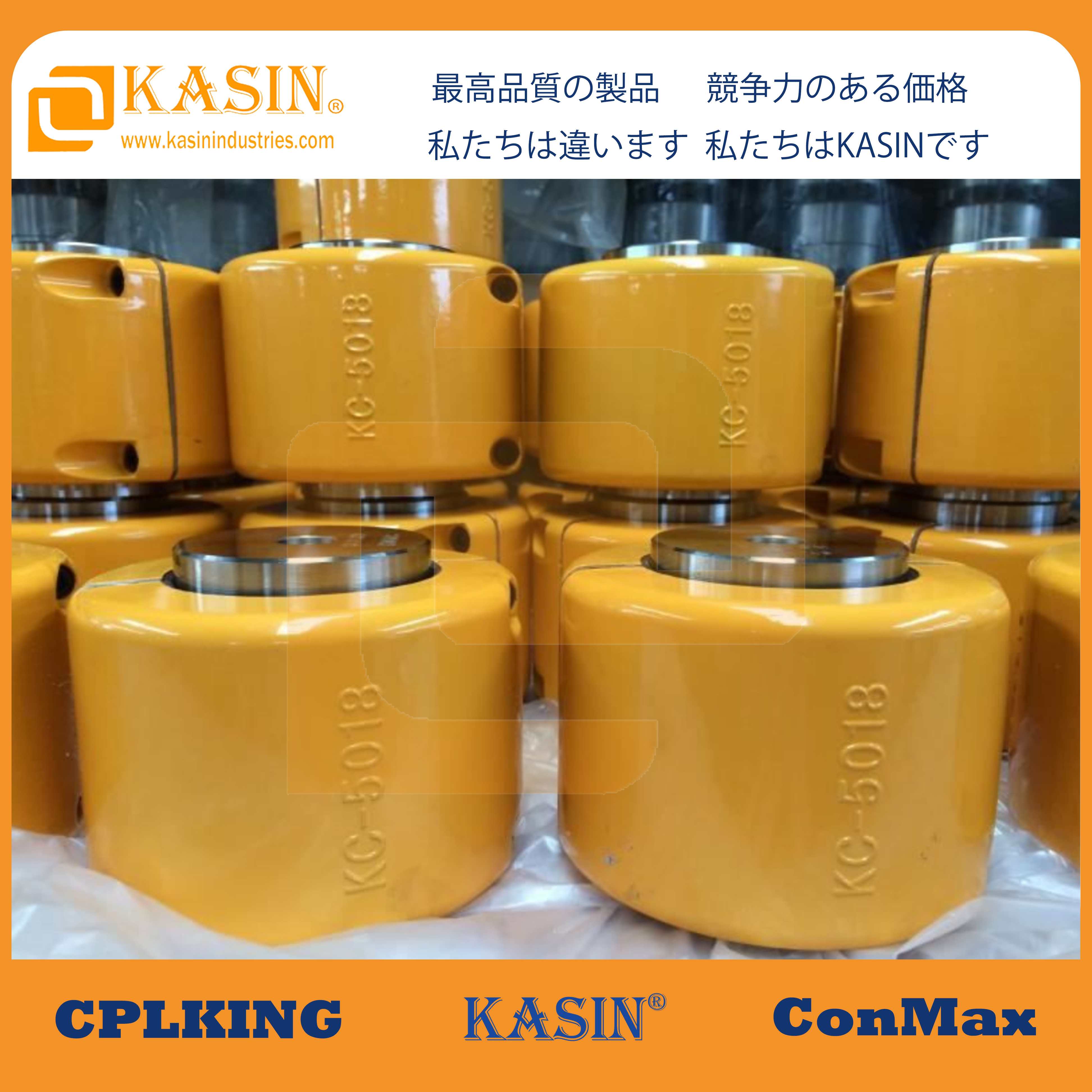

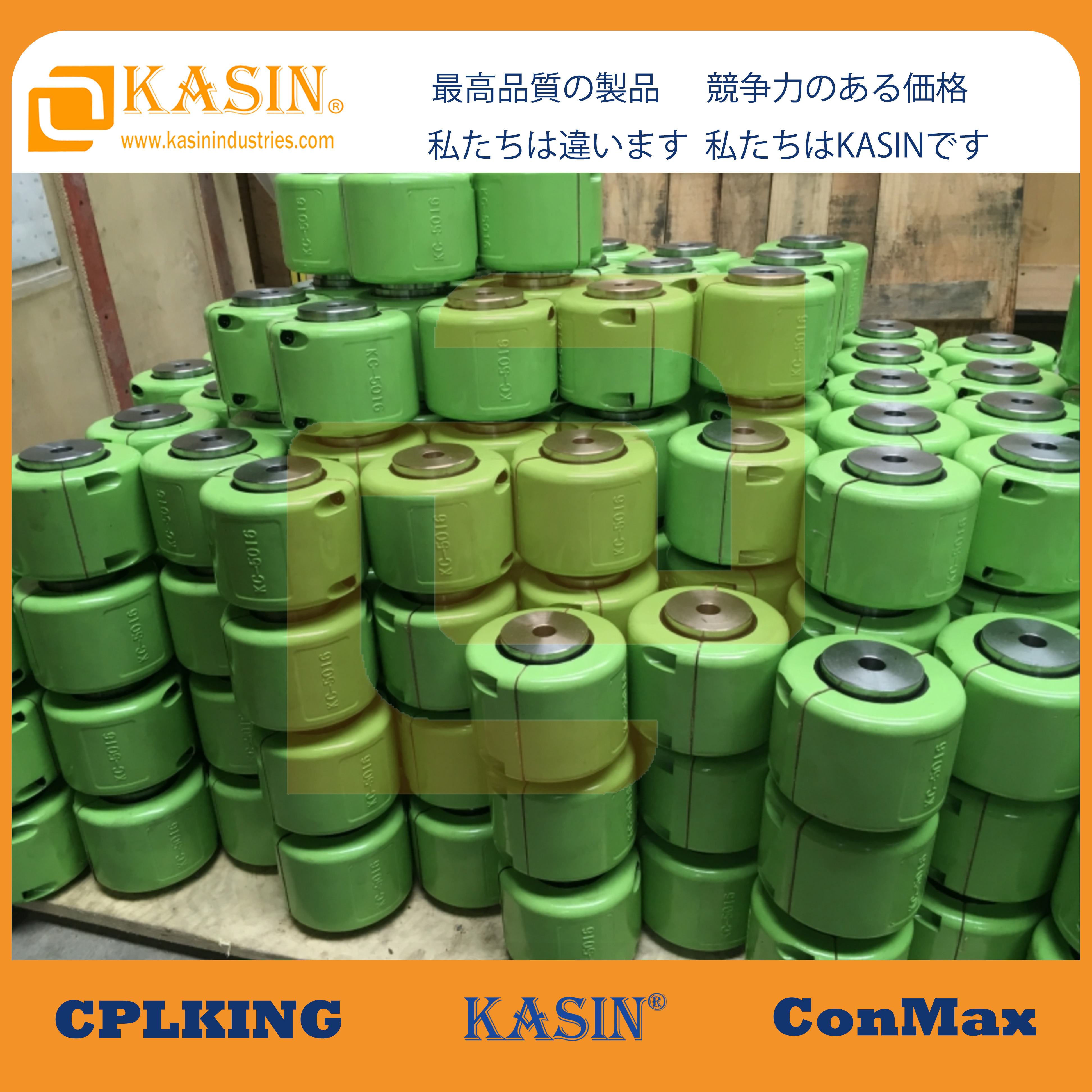

At KASIN INDUSTRIES, we specialize in high-quality chain couplings designed for the toughest industrial environments. Our products are precision-machined, rigorously tested, and available in both standard and custom configurations to meet your unique needs.

Ready to find the perfect chain coupling for your equipment? Contact our team today for expert advice and a free quote!