(1) Stable Transmission, Precise and No Lag

The RGT coupling can achieve stable power transmission without power lag or transmission deviation, adapting to various industrial transmission scenarios with medium and low torque. Whether it is precision testing equipment, automated machine tools, ordinary conveyor equipment or gearbox linkage systems, it can ensure smooth power transmission, avoid equipment failures and reduced production efficiency caused by unstable transmission, and help enterprises achieve stable production. At the same time, its excellent impact resistance can resolve torque fluctuations during operation, avoid deformation, and maintain stable performance after long-term use.

(2) Adapting to Deviations, Reducing Installation Difficulty

During industrial equipment installation, axial deviation and inaccurate installation are inevitable. If the coupling cannot adapt to these deviations, it will aggravate equipment component wear and even cause equipment shutdown. The RGT coupling can flexibly compensate for various axial deviations, greatly reducing the accuracy requirements during equipment installation, saving the time and energy for installation and commissioning, and at the same time relieving the shaft system burden during equipment operation, protecting core equipment components and reducing faults.

(3) Corrosion Resistance and Durability, Adapting to Complex Environments

Industrial production sites often have complex environments such as oil pollution, humidity and dust, which put forward high requirements for the durability of couplings. Through the combination of high-quality materials and process optimization, the RGT coupling has good oil resistance and corrosion resistance, can operate stably for a long time in various complex industrial scenarios, does not need frequent replacement, reduces fault shutdowns caused by environmental factors, and is suitable for metallurgical workshops, food production lines, outdoor storage equipment and other scenarios.

(4) Convenient and Worry-Free, High Cost-Effectiveness

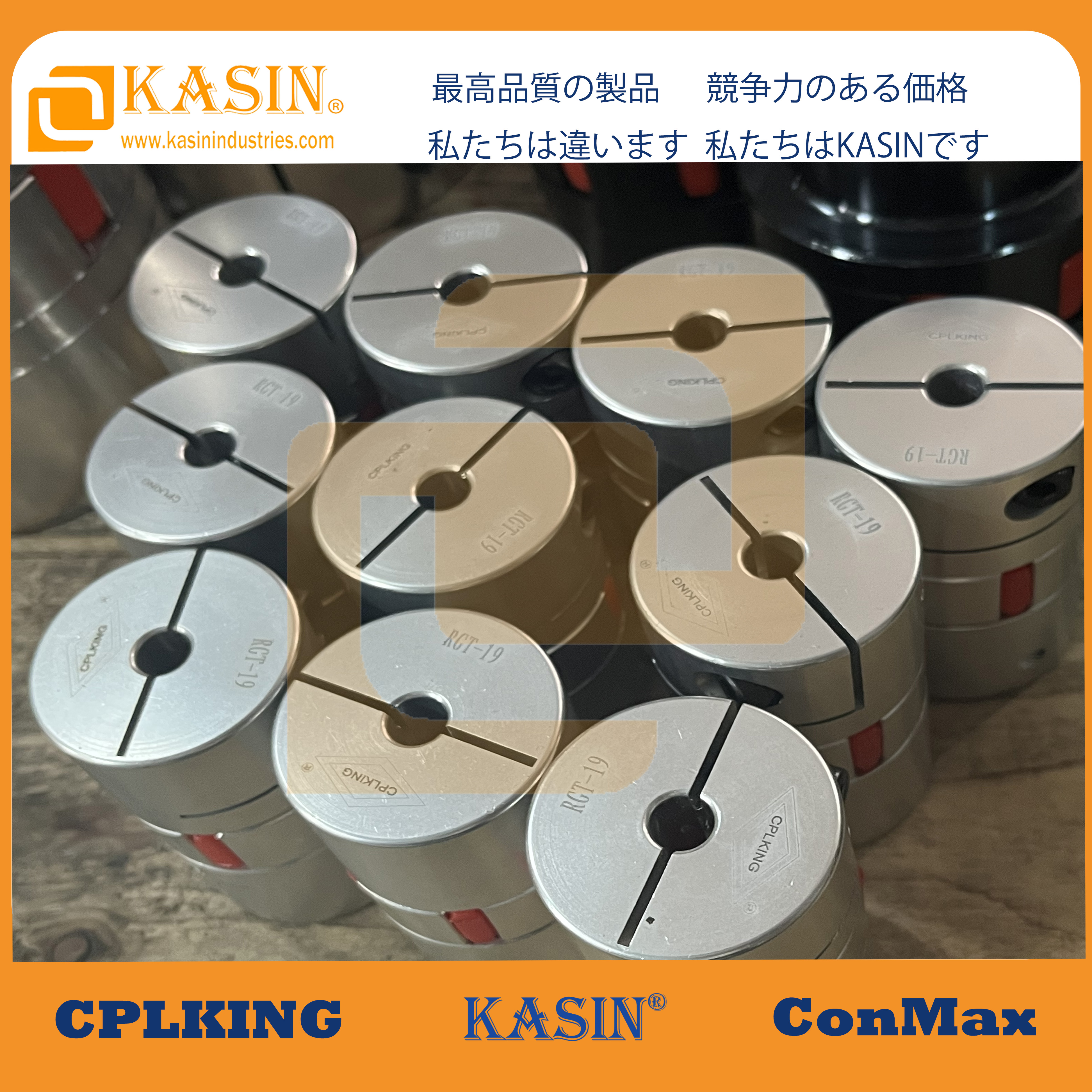

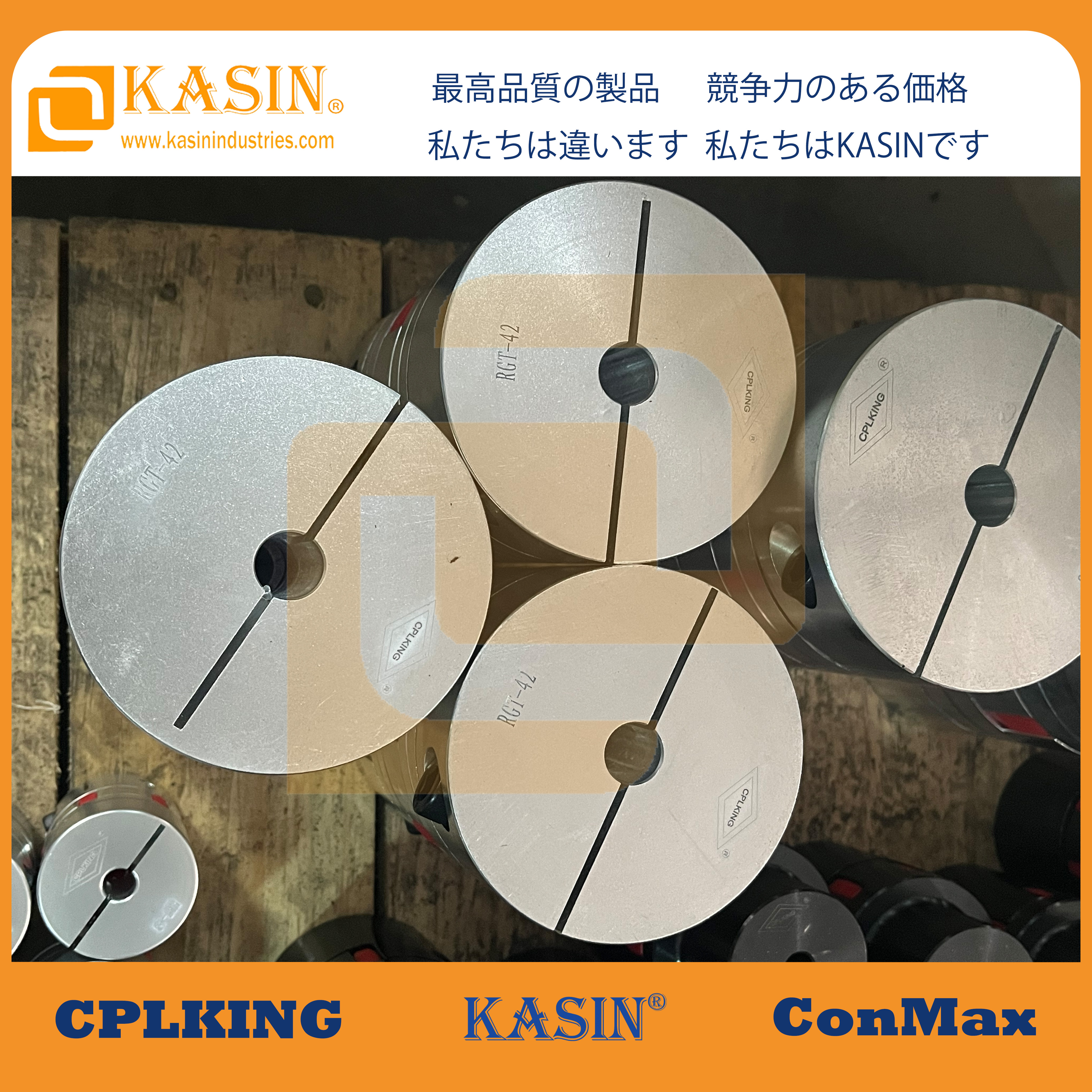

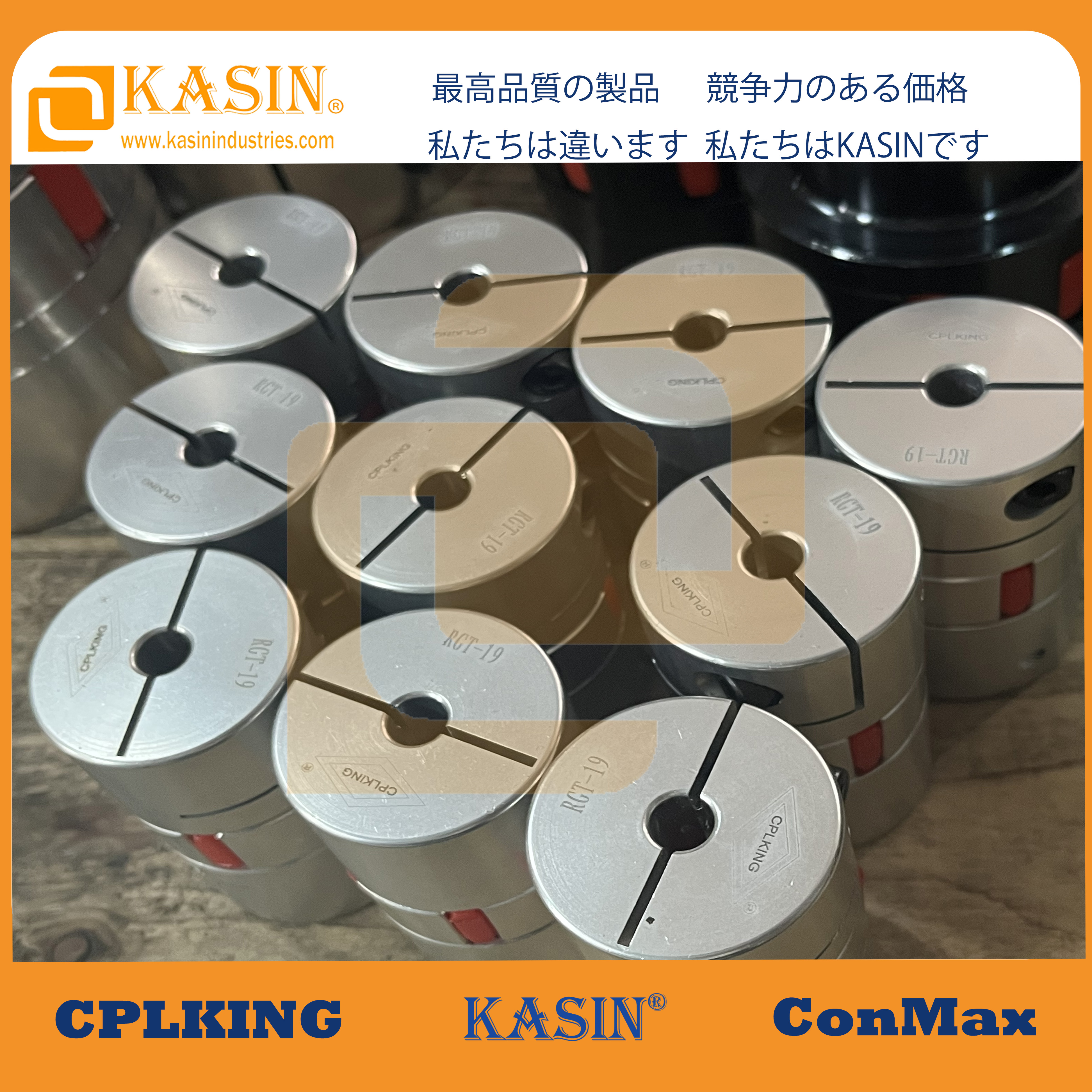

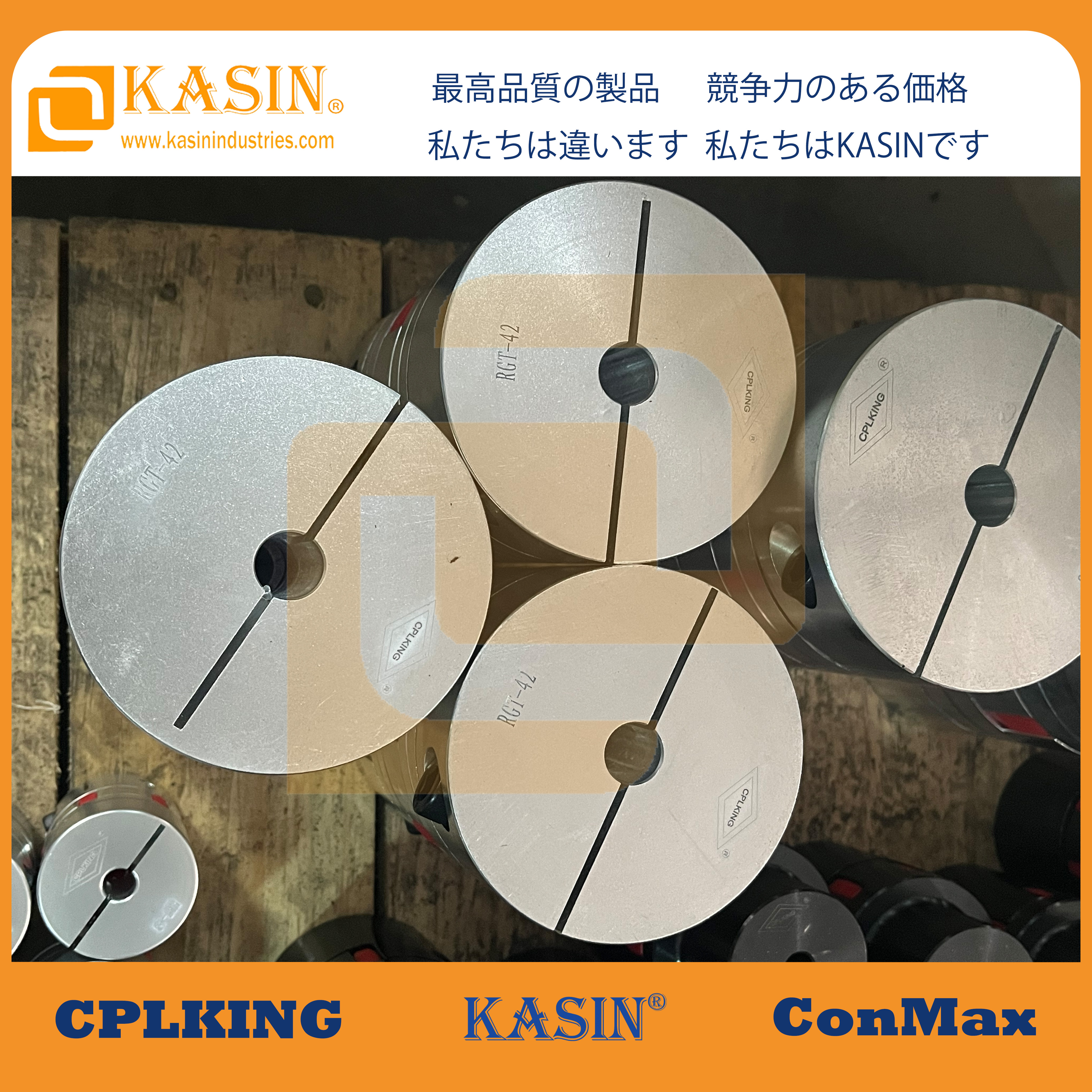

The RGT coupling adopts a compact design, small in size and light in weight, which can adapt to equipment with limited installation space without additional modification to the equipment, and has strong compatibility. At the same time, the overall structure is simple with few components, which not only has a affordable purchase cost, but also is convenient for later maintenance and component replacement. It does not require professional technical personnel or complex tools, can greatly shorten the shutdown maintenance time, reduce the operation and maintenance costs of enterprises, and is a cost-effective choice for small and medium-sized enterprises and batch equipment procurement. In addition, the product does not need frequent lubricant addition, further reducing maintenance links and costs.

III. Application Scenarios and Selection Suggestions: Precise Matching, Worry-Free Use

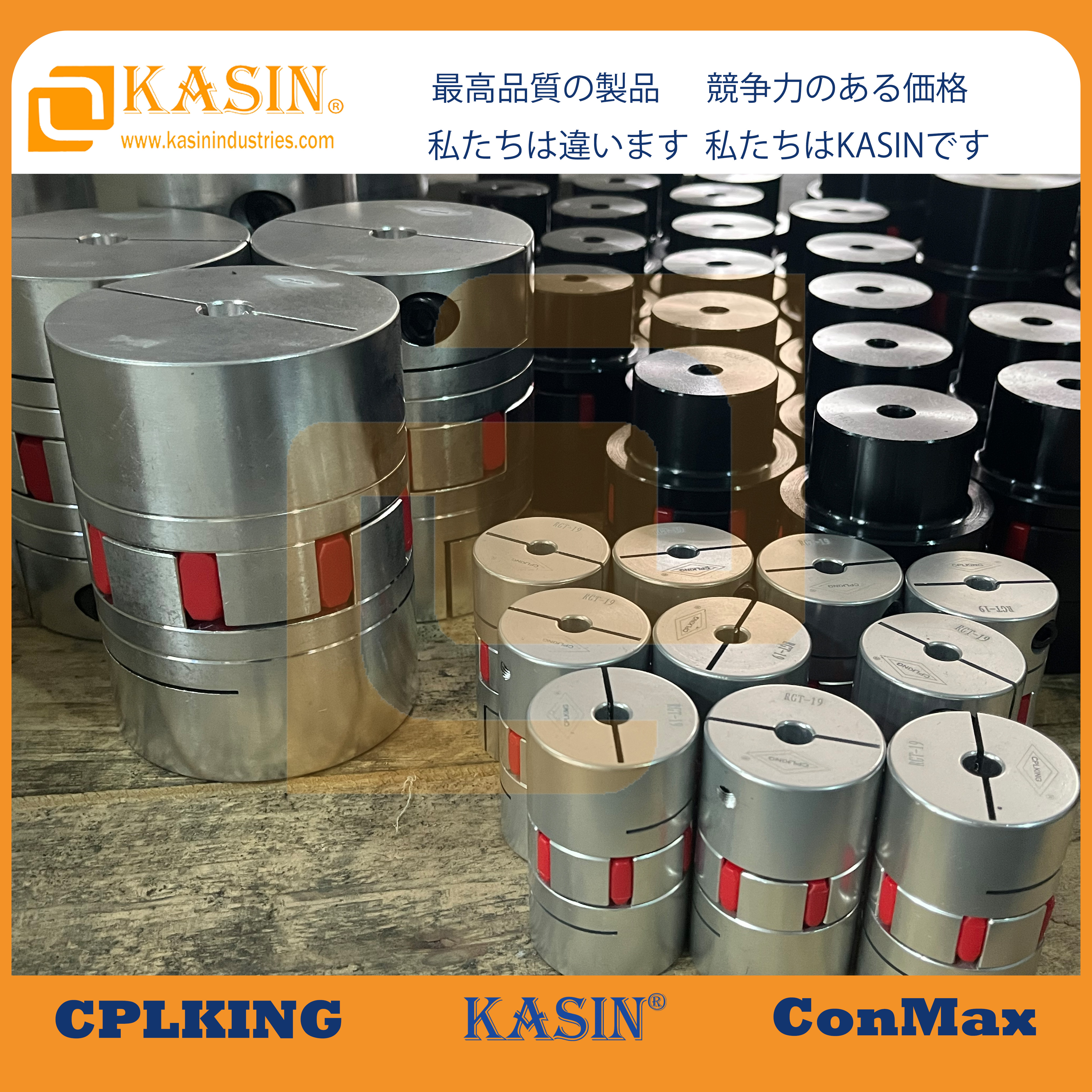

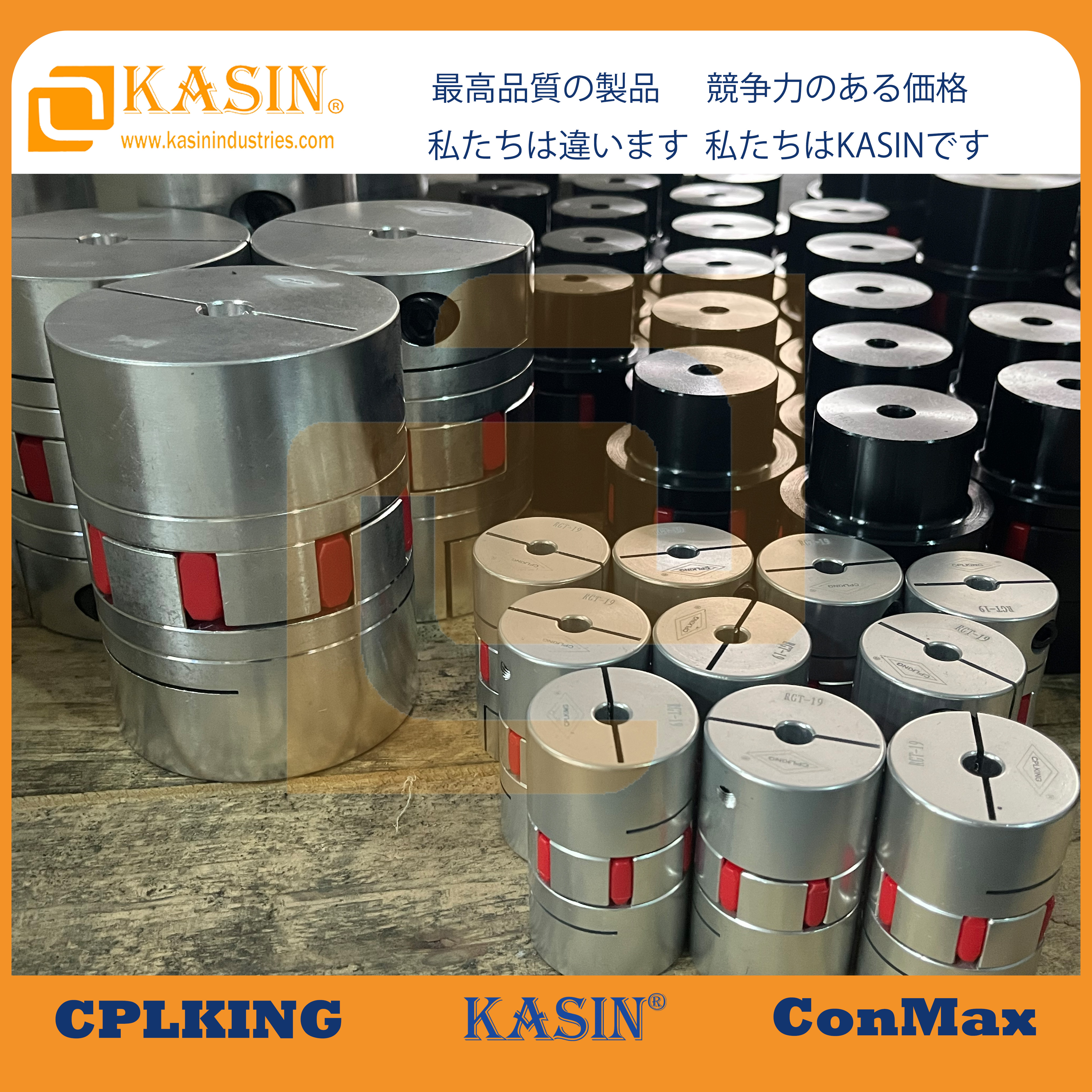

With the characteristics of strong adaptability, stability and durability, the RGT cross ring coupling is widely used in various low-speed, medium and low torque industrial transmission scenarios, mainly adapting to the linkage of various general motors and stepper motors. Common application scenarios include:

Precision Equipment Field: Automated machine tools, measurement and testing instruments, etc., relying on stable transmission performance to ensure equipment operation accuracy;

General Machinery Field: Motor and gearbox linkage, supporting various small reducers, etc., adapting to medium and low torque transmission needs in daily production;

Light Industry and Metallurgy Field: Food processing production lines, small metallurgical auxiliary equipment, etc., the corrosion-resistant and durable characteristics adapt to complex production sites;

Warehousing and Conveying Field: Small conveyors, warehousing and sorting equipment, etc., balancing stability and economy to help improve conveying efficiency;

Other Scenarios: Small and medium-sized water pumps, fans, agricultural machinery auxiliary equipment, etc., adapting to various low-speed, medium and low load transmission needs.

It should be noted that the RGT coupling is not suitable for special scenarios such as high-speed and heavy-load, strong impact, extreme high temperature or strong corrosion. For such needs, you can contact the KASIN technical team to obtain customized transmission solutions.

In terms of selection, no complex calculation is required. It can be matched according to the core factors such as the actual operation needs of the equipment, shaft end size and installation space. KASIN will provide professional selection guidance to help enterprises quickly match suitable models. At the same time, customized processing is supported, and the design can be adjusted according to the special needs of the equipment to adapt to various non-standard scenarios.

IV. Application Cases: Practical Empowerment, Witnessing Practical Value

Over the years, the RGT cross ring coupling has been widely used in industrial scenarios in many countries and regions around the world, serving enterprises in various industries. The following two typical cases intuitively show its practical application value:

Case 1: Supporting Application in Food Conveyor Equipment

Customer Pain Points: A small conveyor equipment of a food processing enterprise had slight installation deviation, and the production site was oily. The original coupling often had problems such as unstable transmission, easy rust and frequent lubricant addition, which not only affected production efficiency, but also increased operation and maintenance costs.

Solution: Combined with the customer's production scenario and equipment needs, a suitable RGT cross ring coupling was recommended. Its flexible deviation compensation capability can resolve equipment installation deviation, the oil-resistant material is suitable for the production site, no lubricant is needed, and the dual fixation design ensures stable transmission and avoids slipping.

Application Effect: After the equipment was installed, the stability of the conveyor operation was greatly improved, with no vibration or noise, completely solving various problems of the original coupling; no frequent maintenance and replacement were required, effectively reducing shutdown time, improving production efficiency, and at the same time reducing operation and maintenance costs and component replacement costs, which was recognized by the customer.

Case 2: Supporting Application in Precision Testing Equipment

Customer Pain Points: A small measuring and testing machine of a testing equipment enterprise had high requirements for transmission accuracy, and the equipment installation space was limited. The original coupling was too large in size and had transmission lag, leading to large deviations in test data and affecting product testing quality.

Solution: A small RGT cross ring coupling was matched for the customer. Its compact size adapts to the limited installation space, the gapless transmission design ensures no power transmission lag, accurately meeting the accuracy requirements of the testing equipment, and the set screw fixation design is convenient for later maintenance.

Application Effect: After the coupling was installed, the transmission accuracy of the testing equipment was greatly improved, the test data deviation was controlled within a reasonable range, and the product qualification rate was significantly increased; the small size does not occupy additional space, the operation and maintenance are convenient, and the equipment operation cost is effectively reduced.

V. KASIN Brand Guarantee: More Than 20 Years of Deep Cultivation, Guarding Stable Transmission

As a brand with more than 20 years of experience in exporting industrial transmission parts, KASIN has always adhered to the principles of quality first and customer-oriented, and has been deeply engaged in the R&D, production and sales of couplings, chains and other industrial transmission parts. With mature production processes, strict quality control, professional technical services and a complete after-sales system, it provides reliable transmission solutions for enterprises around the world. As a core product, the RGT cross ring coupling always focuses on practicality and durability, helping enterprises improve production efficiency.

For the RGT coupling, KASIN provides full-process service guarantees to make enterprise procurement and use worry-free:

Reliable Quality: Every link from raw material procurement to production and delivery undergoes strict inspection to ensure stable and durable products, and prevent unqualified products from entering the market;

Adequate Inventory:

Full inventory of conventional models is available, and orders can be shipped quickly after placement, meeting the needs of emergency equipment procurement and component replacement, and reducing shutdown losses;

Professional Guidance:

It has an experienced technical team that can provide one-on-one selection guidance, installation suggestions, fault diagnosis and other services to solve various transmission problems;

Complete After-Sales Service: It provides standardized return and exchange and maintenance services. During the product warranty period, free maintenance and component replacement services can be enjoyed, and long-term component supply support is provided;

Global Services: Relying on more than 20 years of export experience, it has a complete global logistics and multi-language service capability, and can quickly respond to the needs of global customers.

VI. Conclusion

For industrial enterprises, stable transmission is the foundation of efficient production. A practical and durable coupling can greatly reduce equipment faults and operation and maintenance costs. With the advantages of stable transmission, strong adaptability, convenience and high cost-effectiveness, combined with KASIN's more than 20 years of brand accumulation and full-process service guarantees, the RGT cross ring coupling has become an ideal choice for various low-speed, medium and low torque industrial scenarios.

Whether it is the precise transmission of precision equipment, the stable linkage of production lines, the matching of standardized equipment, or the customized needs of special scenarios, KASIN can provide transmission solutions that meet the needs with the RGT cross ring coupling and professional technical services, helping enterprises achieve efficient production and sustainable development.

If you are looking for a suitable coupling for your equipment, or want to learn about the applicable scenarios and selection suggestions of the RGT cross ring coupling, please feel free to contact the official KASIN customer service and technical team. We will wholeheartedly provide you with professional and thoughtful services to jointly guard every stable operation!

Keywords: RGT Coupling, Cross Ring Coupling, Industrial Transmission Parts, KASIN Coupling, Coupling Selection, Precision Transmission, Low-Speed Heavy-Duty Coupling, Set Screw Coupling, Keyway Coupling.