Roller chains are crucial for the smooth operation of conveyor systems. They provide efficient power transmission and long-lasting durability. Widely used in industries, they handle heavy loads and harsh conditions. In this post, we’ll explore why roller chains are essential for reliable conveyor performance and how they contribute to operational efficiency.

Understanding Roller Chains and Their Role in Conveyor Systems

What are Roller Chains?

Roller chains are mechanical components used in power transmission systems. They consist of interconnected links that help transfer power and motion. Roller chains have been in use for over a century and were first introduced during the Industrial Revolution. Over time, their design has evolved, but their basic function remains the same—moving materials and transferring power efficiently.

How Do Roller Chains Work in Conveyor Systems?

In a conveyor system, roller chains engage with sprockets to transmit power. As the sprockets rotate, the roller chains move, transferring motion to the items on the conveyor. This process ensures materials are moved smoothly along the conveyor belt. Compared to other methods, such as belts or gears, roller chains offer superior efficiency. Unlike belts, they are less prone to slippage, and unlike gears, they can handle higher loads over longer distances.

Key Components of Roller Chains

Roller chains are made up of several key components, each playing a vital role in ensuring smooth conveyor operation:

| Component | Description |

| Rollers | Cylindrical components that reduce friction by rolling over sprockets. |

| Bushings | Located between the rollers, providing a smooth surface for efficient roller movement. |

| Pins | Connect the chain’s links, allowing it to bend and articulate while transferring power. |

| Plates | Flat metal plates that hold the pins and bushings together, forming the chain’s link structure. |

Together, these components work in harmony to ensure smooth, reliable conveyor performance.

Benefits of Using Roller Chains for Conveyor Performance

High Efficiency and Power Transmission

Roller chains are designed to minimize friction, which is key for energy conservation. Less friction means less energy is lost, making roller chains highly efficient in power transmission. This results in smooth and reliable movement of materials along conveyors, ensuring consistent performance over time.

Durability and Longevity

Roller chains are built to endure heavy loads and shock forces, which makes them ideal for tough industrial environments. They can handle abrasive conditions without breaking down quickly. This durability reduces the frequency of replacements, lowering maintenance costs and extending the chain’s lifespan, even under harsh conditions.

Versatility and Customization

Roller chains come in different types to meet various conveyor needs. Whether it’s powered, gravity, or overhead systems, roller chains can be adapted to fit. They are also highly customizable. You can adjust their lengths, add attachments, or change configurations to suit specialized applications, making them perfect for a range of industries.

Cost-Effectiveness

Compared to other power transmission systems, roller chains offer a cost-effective solution. Their durability and low maintenance needs mean fewer replacements and lower operational costs over time. In the long run, they often prove to be a more economical choice than belts or gears.

Types of Roller Chains and Their Applications in Conveyors

Standard ANSI Roller Chains

Standard ANSI roller chains are the most commonly used type in industrial conveyor systems. They come in various sizes, identified by a three-digit number (e.g., 40, 50, 60). These chains are versatile, reliable, and suitable for most general conveyor applications. They are widely used due to their ease of installation and maintenance.

Heavy Series ANSI Roller Chains

Heavy Series ANSI roller chains are designed for environments that require extra strength and durability. These chains feature thicker link plates, making them ideal for high-strength and high-shock load situations. They’re commonly used in industries like construction, mining, and heavy manufacturing, where conveyors handle large, heavy items.

Double Pitch Conveyor ANSI Roller Chains

Double pitch conveyor ANSI roller chains are known for their longer pitch, which makes them suitable for light to medium-duty applications. These chains provide smoother operation over longer distances and are often used in conveyor systems that require lower speeds and less frequent maintenance. They offer cost-effectiveness for applications like material handling and packaging.

Attachment Roller Chains

Attachment roller chains come equipped with special links, such as extended pins or tabs, allowing them to attach custom fixtures. These chains are essential in specialized applications where products need to be processed or moved along the conveyor with additional components. Industries like automotive manufacturing and packaging often rely on attachment roller chains.

British Standard Metric Roller Chains

British Standard Metric roller chains are similar to ANSI chains but adhere to metric dimensions. These chains are commonly used in European and Asian markets, offering the same high performance and durability as ANSI chains. They are ideal for regions that require standardization according to ISO or other metric-based regulations.

How to Choose the Right Roller Chain for Your Conveyor System

Factors to Consider When Selecting a Roller Chain

Load Capacity

The chain must be able to handle the maximum load of your conveyor system. It’s important to match the chain's strength with the weight it will carry to prevent premature wear or breakage.

Environmental Conditions

Conveyor systems often operate in challenging environments. Factors like temperature, humidity, and exposure to chemicals can affect chain performance. Choose a roller chain that’s resistant to these conditions to ensure long-lasting reliability.

Speed

Align the chain's speed rating with your conveyor system's operational speed. A chain that can’t handle the required speed will experience excessive wear and potential failure.

Maintenance Requirements

Consider the chain’s maintenance needs. Opt for roller chains that require minimal upkeep, especially for systems where downtime is costly. Regular lubrication and inspection are key to maximizing chain life.

How to Determine the Right Size and Pitch for Your Conveyor System

Selecting the right size and pitch is crucial for ensuring smooth operation. The size depends on the load it will carry, the speed of the system, and the specific application. Larger loads generally require a larger pitch, while smaller loads can use smaller chains. A chain that’s too small for the load can wear out faster, while one that’s too large may result in inefficiency.

| Step | Description |

| Step 1: Determine the Load | Measure the weight of the items being conveyed. A larger load will require a chain with greater strength. |

| Step 2: Choose the Correct Pitch | Based on the load and application, select a pitch that ensures reliable performance without excessive wear. Consult manufacturer guidelines for specific pitch recommendations. |

| Step 3: Consider Application-Specific Needs | Some applications, such as high-speed or high-impact environments, may need specialized chains designed for those conditions. |

Enhancing Conveyor System Reliability with Roller Chains

Optimizing Conveyor Performance with the Right Roller Chain

Selecting the correct roller chain is crucial for the smooth and efficient operation of conveyor systems. The right chain ensures power is transferred efficiently, reducing energy loss and maintaining consistent speed. It also contributes to the longevity of the system by minimizing wear and tear, which leads to less frequent breakdowns and maintenance. When a reliable roller chain is in place, downtime is minimized, allowing for continuous operations.

Case Studies: Successful Use of Roller Chains in Conveyor Systems

Many industries rely on roller chains to enhance their conveyor system performance:

Automotive Manufacturing: In automotive assembly lines, roller chains ensure the smooth movement of parts through various stages of production. These chains are essential for handling heavy loads and operating at high speeds.

Food Processing: In food packaging and bottling, roller chains provide durability and maintain hygienic standards. Their reliability ensures that production lines keep moving without unnecessary interruptions.

Mining: Roller chains are used in harsh conditions to transport heavy materials over long distances. Their ability to withstand tough environments helps reduce the frequency of costly repairs.

The Future of Roller Chains in Conveyor Systems

Innovations in roller chain technology are constantly improving conveyor system reliability. Advanced materials are being used to make chains more resistant to wear, corrosion, and extreme temperatures. Additionally, new lubrication systems are designed to reduce friction and increase efficiency. As technology advances, roller chains will continue to evolve, offering even better performance and greater longevity for conveyor systems.

Conclusion

Roller chains are essential for conveyor systems due to their efficiency, durability, and cost-effectiveness. They minimize energy loss, reduce wear, and ensure smooth operations. These chains handle heavy loads, resist harsh conditions, and require minimal maintenance. Ultimately, roller chains are crucial for enhancing the reliability and performance of conveyor systems across various industries.

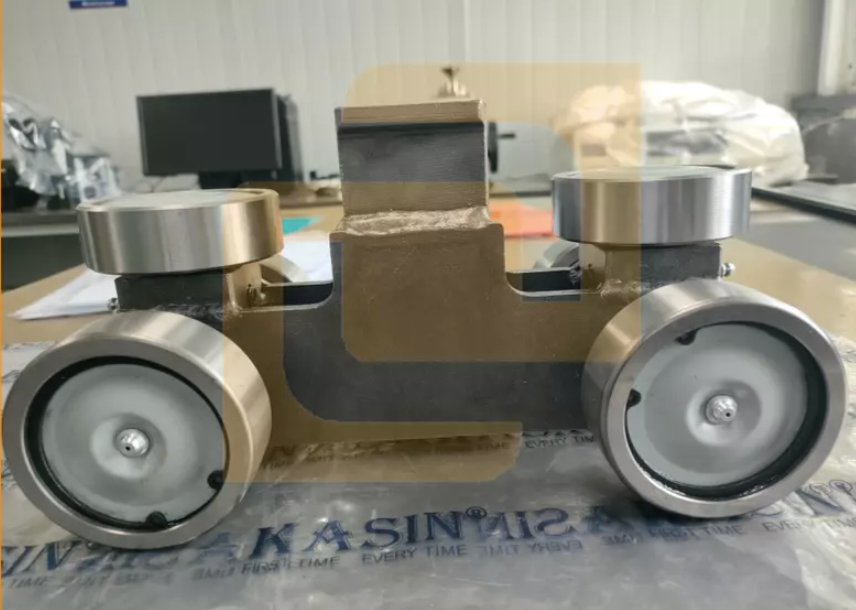

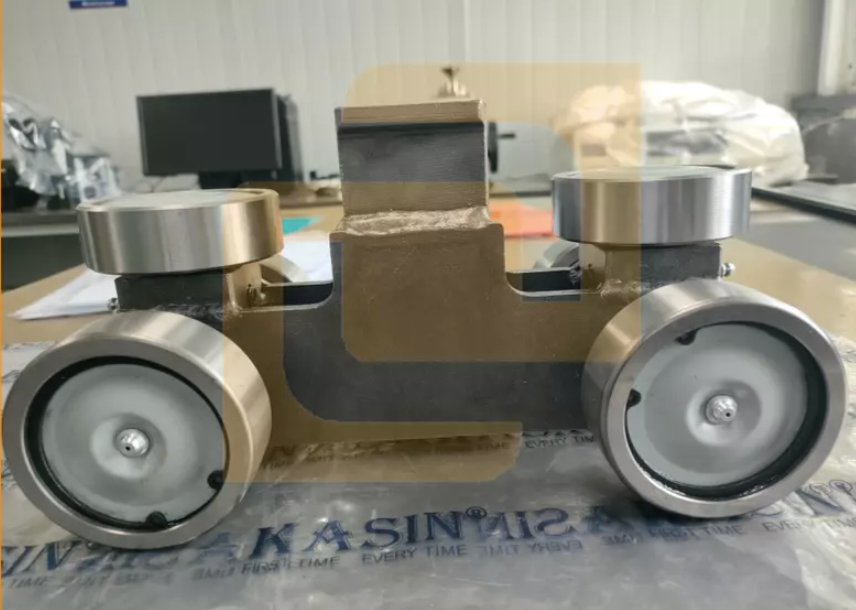

Kasin a major manufacturer specializing in chains after more than 20 years of development, has been among the chain industries. Contact us for inquiries or custom solutions tailored to your needs.

FAQ

Q: What are roller chains and why are they important in conveyor systems?

A: Roller chains are mechanical components used to transfer power in conveyor systems. They reduce friction, handle heavy loads, and ensure smooth material movement, making them essential for efficient and reliable performance.

Q: How do roller chains improve conveyor system performance?

A: Roller chains provide high efficiency by minimizing energy loss, reduce wear and tear, and help maintain consistent speed, contributing to minimal downtime and longer system lifespan.

Q: What types of roller chains are commonly used in conveyors?

A: Common types include standard ANSI roller chains, heavy-duty ANSI chains, double-pitch conveyor chains, attachment chains, and British Standard metric roller chains, each suited for different applications.