SFC-Coupling

The kasin SFC-Coupling We have a choice of highly performing sleeves, EPDM, Neoprene and Hytrel 2. EPDM and Neoprene admit a torsion flex of 15o, and Hytrel a much less, 7o. In revenge, Hytrel transmits around four times as much power as the equivalent EPDM or Neoprene.

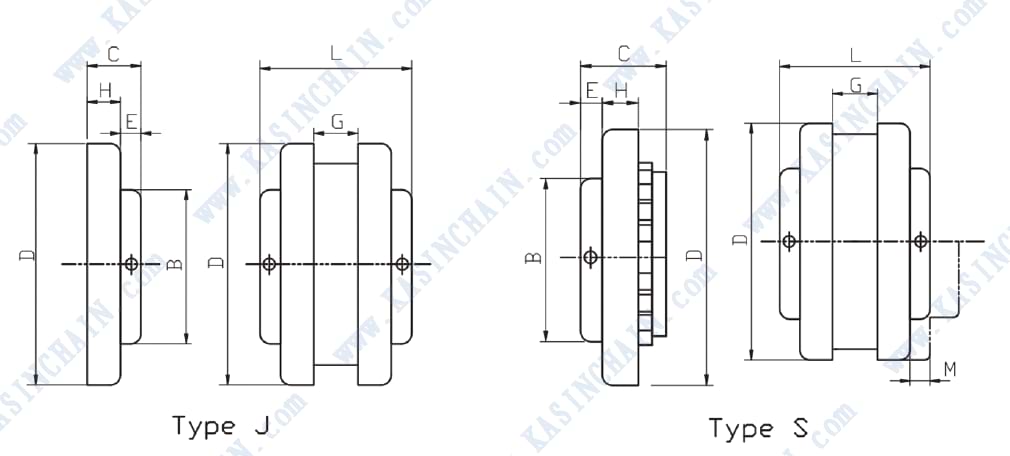

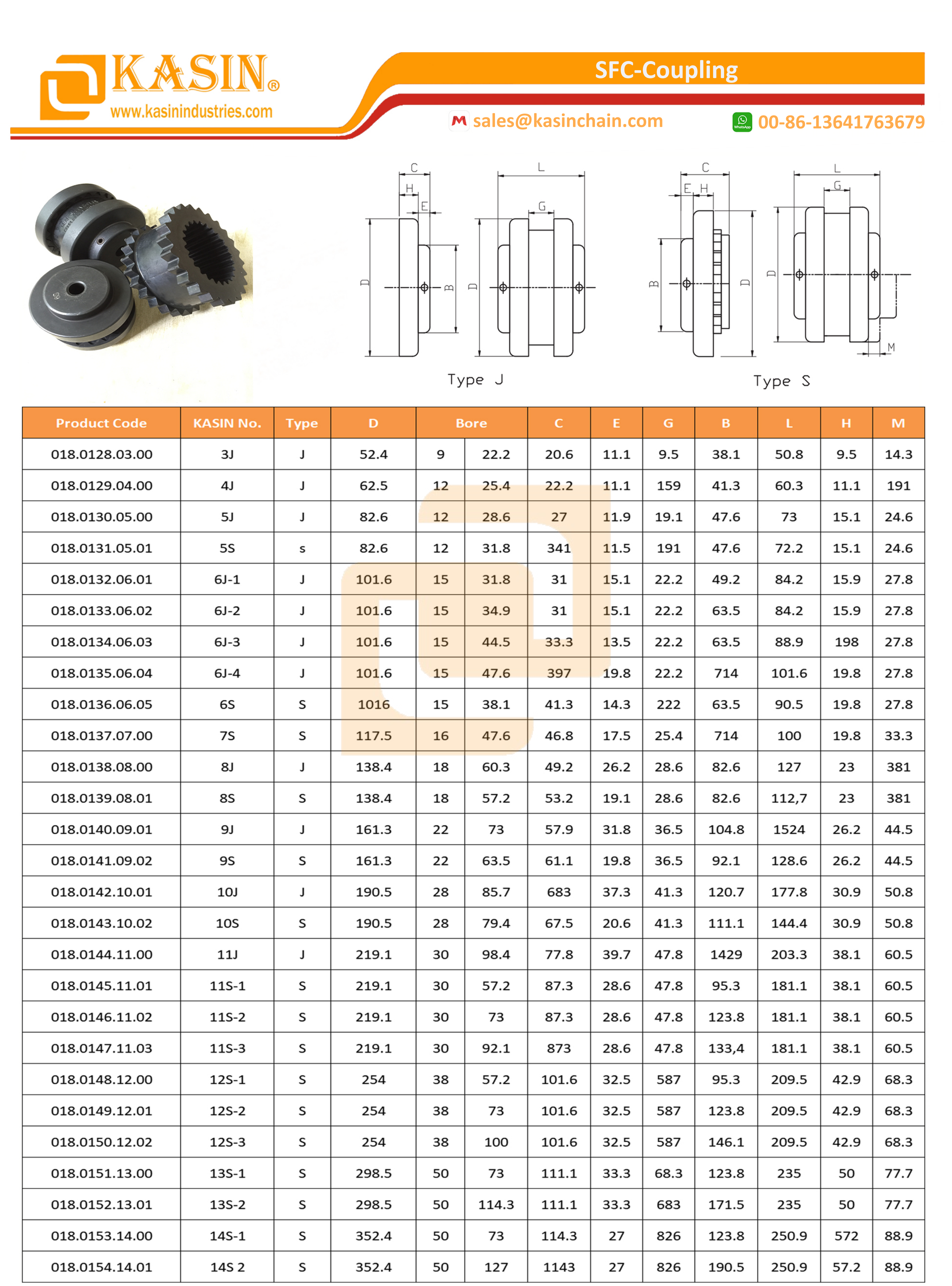

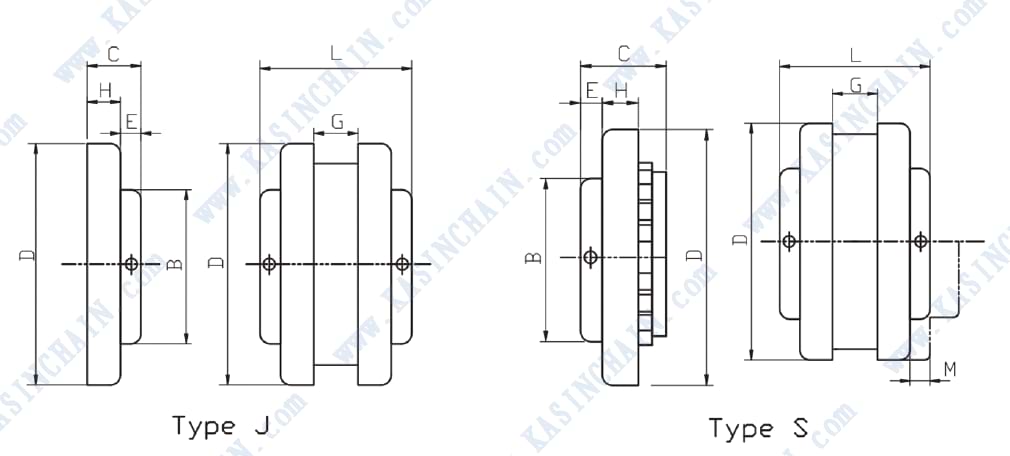

There are two Series available, the J and the S.

At the time of choosing the best adapted size for the power transmis- sion application, it is important to ascertain the type of load-torque transmitted and in consequence apply a service factor accordingly. We distinguish three service factor levels as, light, medium and hea- vy.

EPDM: Ethylene, Propylene, Diene, Monomer. Synthetic elastomer of SHA hardness from 50 to 65, Tensile strength from 3 to 14 MPa according grade. Mainly used as elastomer in exter- nal applications. Resists to aging, ozone, UV rays, water and environmental action. Resist to abrasion, to acids, alkaline and a range of temperature from -40oC to 120oC.

1 EPDM: Ethylene, Propylene, Diene, Monomer. Synthetic elastomer of SHA hardness from 50 to 65, Tensile strength from 3 to 14 MPa according grade. Mainly used as elastomer in exter- nal applications. Resists to aging, ozone, UV rays, water and environmental action. Resist to abrasion, to acids, alkaline and a range of temperature from -40oC to 120oC.

2 Hytrel: Thermoplastic polyester elastomer developed by Dupont. Highly performing after combining the features of elastomers and flexibility of plastic materials. It is tough, resistant to fatigue, to impact and to creeping. Stands up to a wide range of tempera- tures, resistant to chemicals and very versatile, as there is a wide choice of grades to adapt to a particular application. Has an operative temperature of -54oC to 121oC