Material handling systems are crucial for industries like cement, automotive, and mining. They ensure smooth, continuous movement of materials, but they face challenges like downtime and maintenance issues. Forged scraper chains help tackle these problems by offering increased durability and efficiency. In this post, we’ll discuss how these chains improve material handling systems by reducing interruptions and improving performance.

What Are Forged Scraper Chains and Why Are They Important?

Definition of Forged Scraper Chains

Forged scraper chains are specially designed components used in material handling systems. These chains are made by forging high-strength steel, ensuring they can handle heavy loads and harsh environments. Unlike other types of chains, forged scraper chains are known for their durability and resistance to wear, making them ideal for continuous operation in industrial settings.

What sets them apart from other chains is their ability to resist elongation over time, reducing the need for frequent replacements. They are typically made from materials like alloy steel or stainless steel, which provide excellent strength and corrosion resistance.

Role of Forged Scraper Chains in Material Handling Systems

Forged scraper chains play a critical role in moving materials through bulk handling systems. They are commonly used to transport heavy materials like coal, ash, and grains across various industries. These chains ensure a smooth flow of materials without the frequent interruptions caused by other types of chains.

Industries such as automotive, cement, and mining benefit significantly from forged scraper chains. They help keep conveyor systems running continuously, reducing downtime and boosting overall productivity. The robust construction of these chains makes them suitable for a wide range of applications, from moving raw materials to transporting finished products.

Key Benefits of Using Forged Scraper Chains in Material Handling

| Benefit | Description |

| Reduced Downtime | Forged scraper chains reduce the frequency of replacements and repairs, leading to fewer system stoppages. |

| Systems using forged chains experience up to 30% less downtime compared to non-forged chains. |

| Increased Efficiency | Forged chains improve material flow, minimize friction, and reduce energy consumption. |

| In industries like cement and automotive, they boost operational efficiency and lower costs. |

| Enhanced Durability & Reliability | Made from high-strength materials, forged chains resist wear, corrosion, and harsh environments. |

| Their long lifespan means fewer replacements and reliable, long-term performance. |

| Continuous Operation | Forged scraper chains reduce breakdowns, ensuring smooth, uninterrupted operations in industries like cement and automotive. |

| Inferior chains cause delays; forged chains help avoid malfunctions and keep production lines running smoothly. |

How Forged Scraper Chains Contribute to Cost-Effectiveness

Long-Term Savings on Maintenance

While forged scraper chains may have a higher initial cost, they offer significant long-term savings. Their durability means fewer replacements and less frequent maintenance. This reduces the overall cost of ownership over time.

For example, in the cement industry, businesses have saved thousands of dollars annually on repair costs by switching to forged chains. These chains can last up to 50% longer than non-forged alternatives, making the investment worthwhile.

When considering forged scraper chains, businesses should factor in these long-term savings. By reducing downtime and maintenance, forged chains provide a more cost-effective solution in the long run.

Reduced Operational Interruptions

Forged scraper chains minimize the number of breakdowns, directly increasing system uptime. Fewer breakdowns mean production runs smoothly without unexpected halts, resulting in more productive hours and fewer interruptions.

With reduced maintenance needs, there are fewer disruptions in production schedules. This boosts operational efficiency and ensures products are delivered on time.

For companies, optimizing operational efficiency directly impacts the bottom line. The more consistent the production, the higher the potential revenue, making forged scraper chains a smart financial choice.

How Do Forged Scraper Chains Enhance Material Handling System Performance?

Forged scraper chains are designed with precision, which ensures smoother and more efficient operations. The manufacturing process minimizes imperfections, leading to a consistent, smooth movement along the conveyor.

Minimal friction is essential for maintaining optimal performance. Less friction reduces the wear and tear on both the chains and the materials being moved, resulting in less energy consumption and lower maintenance costs.

The uniform design of forged scraper chains prevents jamming and misalignment in conveyor systems. This consistent performance helps avoid costly disruptions, ensuring a steady flow of materials and preventing system failures.

Forged scraper chains are built with high-strength materials, ensuring secure attachment and reliable operation. This reduces safety risks associated with chain failures or detachment during operation.

Safety is a significant concern in material handling, especially in industries where heavy and abrasive materials are transported. The durability of forged scraper chains minimizes the risk of accidents, offering a safer working environment for operators.

By using high-strength materials, these chains are more resistant to stress and strain, preventing failures and ensuring the smooth operation of material handling systems. This makes forged scraper chains a reliable safety solution in demanding industrial environments.

Versatility Across Industries and Applications

One of the key benefits of forged scraper chains is their versatility. These chains can adapt to a variety of materials and operating conditions, from handling heavy metals in mining to more delicate materials in agriculture.

Industries such as mining, recycling, and agriculture rely on the ability of forged scraper chains to handle different types of materials. The chains can operate at various speeds and are equipped to deal with diverse material types, making them highly adaptable to different industrial needs.

Forged scraper chains also perform well in extreme conditions, whether exposed to high temperatures or harsh, abrasive environments. This versatility makes them a preferred choice for a wide range of applications across multiple industries.

How Can Forged Scraper Chains Be Customized for Specific Needs?

Custom Attachments and Flight Configurations

Forged scraper chains can be customized with specific attachments and flight configurations to suit particular applications. These modifications allow the chains to handle different materials or operate in unique environments.

For instance, in the mining industry, chains can be fitted with specialized flights to carry larger, heavier materials. In food processing, more delicate attachments are used to handle grains or powders without damaging them.

Tailoring Chains to Handle Different Materials and Environments

Forged scraper chains can be designed to handle various materials, such as grains, coal, or cement. Modifications like chain thickness, attachment shapes, and flight designs ensure optimal material handling.

For extreme environments, such as high temperatures, moisture, or abrasive conditions, chains are made with corrosion-resistant materials or heat-treated for extra durability. These modifications ensure the chains last longer in tough conditions, reducing the need for frequent replacements.

Working with Manufacturers for Custom Solutions

When customizing forged scraper chains, it’s important to work closely with manufacturers. They can design chains that meet specific business needs, ensuring compatibility with unique systems or materials.

Collaborating with experts is crucial for achieving the best material handling solution. Manufacturers can offer tailored advice on materials, design, and modifications, ensuring the chains perform efficiently and last longer.

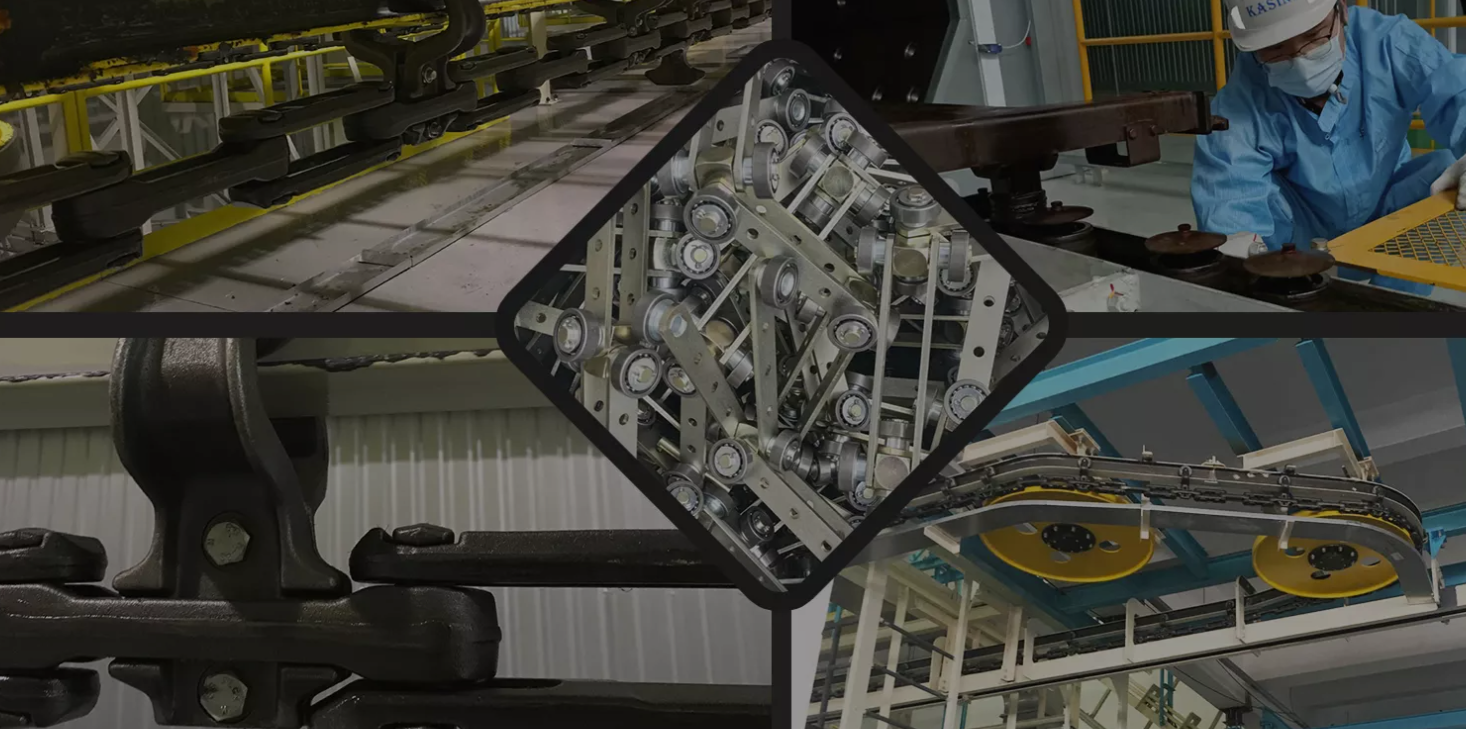

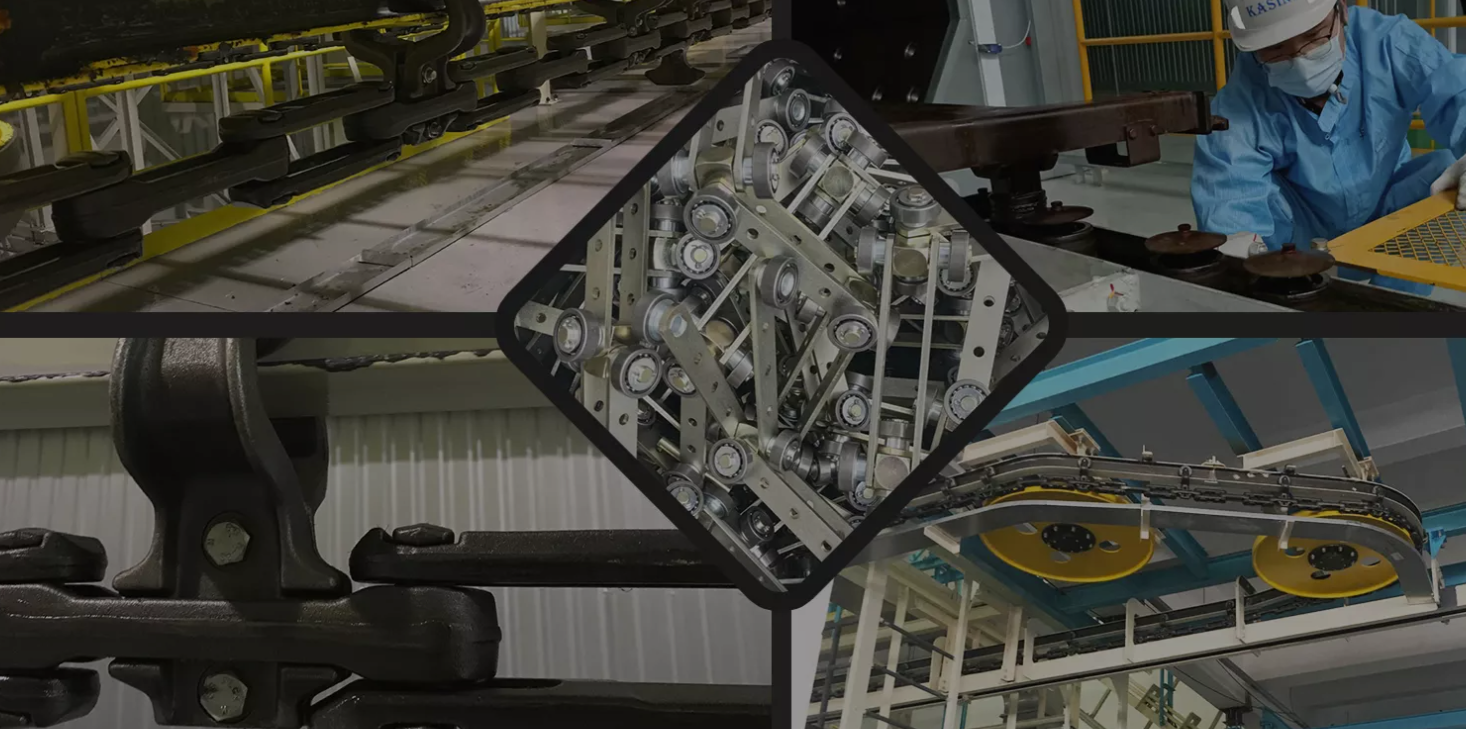

Kasin

Kasin a major manufacturer specializing in chains after more than 20 years of development, has been among the chain industries. As one of the largest manufacturers in the Chinese market of chain and power transmission components, our experience and adaptability are unparalleled.

We have teams of engineers in different Chinese cities and in different countries who are able to produce tailor-made solutions for any industrial application.Contact us for inquiries or custom solutions tailored to your needs.

Conclusion

Forged scraper chains offer major benefits in material handling efficiency. They reduce downtime, enhance safety, and improve system performance. Their durability and design make them a cost-effective long-term solution.

Investing in forged scraper chains can boost productivity while cutting operational costs. Businesses should consider these chains to optimize their material handling systems and ensure reliable, continuous operation.

FAQ

Q: How long do forged scraper chains last?

A: The lifespan of forged scraper chains is significantly longer than non-forged chains due to their durable construction. Factors such as the operating environment, load, and maintenance affect their longevity. On average, forged chains last up to 50% longer than non-forged chains, offering more value over time.

Q: Are forged scraper chains expensive?

A: While the initial cost of forged scraper chains is higher, they offer long-term savings. Their durability reduces maintenance and replacement costs. Businesses can justify the investment by considering the reduced downtime and fewer replacements required over time.

Q: Can forged scraper chains be used in extreme environments?

A: Yes, forged scraper chains perform well in extreme environments such as high heat, moisture, and abrasive conditions. Their high-strength materials and heat treatment ensure they resist wear, corrosion, and stress, making them ideal for demanding applications like mining and cement manufacturing.

Q: What maintenance is required for forged scraper chains?

A: Forged scraper chains require basic maintenance, including regular inspections and lubrication to reduce friction. Proper maintenance can significantly extend the lifespan of the chains, reducing the need for costly repairs and replacements.