In the highly competitive world of modern manufacturing, operational efficiency is everything. Companies invest millions in automation, digital monitoring, and lean production systems. Yet, one often-overlooked factor can quietly undermine productivity and inflate operating costs: downtime and maintenance caused by unreliable material handling equipment—especially conveyor systems.

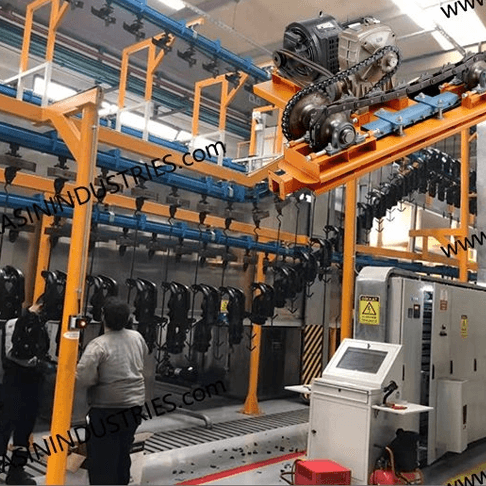

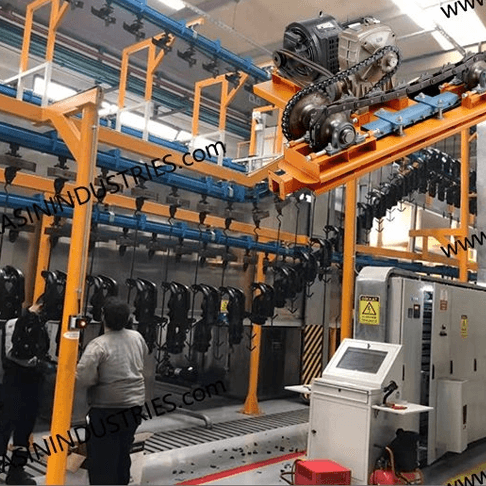

Among all conveying technologies, the overhead chain conveyor plays a pivotal role in moving materials through multiple stages of production while maximizing floor space. However, not all overhead conveyors are built equally. Choosing a durable and well-engineered overhead chain conveyor system can dramatically reduce unplanned downtime, lower maintenance expenses, and improve your facility’s overall equipment effectiveness (OEE).

Why Downtime and Maintenance Costs Matter More Than Ever

Today’s factories are under constant pressure to increase throughput, maintain consistent quality, and keep production flowing 24/7. But unplanned downtime can bring operations to a halt—sometimes for hours or even days.

Every minute your overhead chain conveyor is down, you’re losing:

Production capacity

Labor efficiency

Delivery timelines

Customer satisfaction

Revenue

More importantly, frequent maintenance and repairs on low-durability conveyors lead to hidden costs:

Excessive spare part usage

Overworked maintenance teams

Higher risk of accidents

Expensive emergency service calls

The solution? Invest in durable overhead chain conveyor systems that are designed for reliability, long service life, and low maintenance.

Understanding Overhead Chain Conveyor Systems

An overhead chain conveyor is a continuous loop system suspended from the ceiling or an elevated frame, using chain links and trolleys to carry items through various process stations. These systems are ideal for:

Space-constrained production environments

Multi-stage manufacturing lines

Paint booths, ovens, and cooling zones

Component assembly and inspection

Inward/outward material transfers

Overhead conveyors are commonly used in automotive, metalworking, appliance, furniture, electronics, textile, and food processing industries.

Common Causes of Conveyor Downtime

While the concept of an overhead chain conveyor may appear simple, ensuring its continuous and reliable operation depends on the smooth interaction of multiple mechanical components. When any one of these parts fails or degrades, the entire system can suffer, resulting in costly downtime. Below are the most common causes of unplanned conveyor downtime and how they typically impact industrial operations.

1. Chain Elongation or Stretching

One of the primary reasons overhead chain conveyors experience performance issues is chain elongation. Over time, due to constant exposure to tensile forces and the weight of suspended loads, chain links made from substandard or low-grade materials begin to stretch. This stretching can result in:

Poor engagement with sprockets: Misalignment between the chain and sprockets causes skipping, jerky motion, and even chain slippage.

Irregular load spacing: As chain pitch expands unevenly, loads may become unbalanced or mispositioned along the route.

Derailment or jamming: In severe cases, a stretched chain can derail from the track entirely, causing a full system shutdown.

Regular monitoring and the use of high-quality, stretch-resistant materials are essential to mitigate this issue.

2. Component Wear and Tear

Conveyor systems contain numerous moving parts—rollers, pins, bushings, and guide tracks—all of which are exposed to continuous friction and mechanical stress. In high-speed or high-load environments, these components wear out faster, especially if:

The conveyor operates continuously without scheduled rest intervals

Loads exceed the system’s rated capacity

Environmental factors such as dust or moisture accelerate wear

Failure to replace worn parts on time can lead to catastrophic mechanical failure, which may require costly repairs and prolonged downtime.

3. Insufficient Lubrication

Lubrication plays a critical role in reducing friction between moving parts. However, manual lubrication routines are often overlooked or inconsistently performed, leading to:

Increased surface friction and heat generation

Accelerated wear of pins and rollers

Potential overheating in high-temperature zones, increasing fire risk

Inadequate lubrication not only shortens component lifespan but also introduces serious safety concerns in industrial settings.

4. Track Obstruction or Misalignment

As overhead chain conveyors traverse complex layouts—including curves, inclines, and multi-level routing—precise track alignment becomes essential. Over time, however, these tracks can shift due to:

When the track is misaligned or obstructed (e.g., by debris or wear debris buildup), the chain may jam, experience excessive wear at bends, or fail to return to the drive mechanism, resulting in unexpected system halts.

How Durable Conveyor Design Reduces Downtime

Reducing unplanned stoppages starts with selecting the right equipment. Not all overhead chain conveyor systems are created equal. Manufacturers like KASIN Industries understand that long-term reliability is not just a value-add—it’s a necessity.

KASIN’s systems are engineered with durability at the core, integrating material science, mechanical precision, and advanced manufacturing techniques. Let’s examine how KASIN’s conveyor design choices directly translate into lower maintenance needs and minimized downtime.

1. High-Quality Materials for Maximum Strength

KASIN uses 16# medium-carbon steel for the chain structure and EN8-grade hardened rollers to achieve superior mechanical performance. These materials offer:

Higher tensile strength, which allows the chains to carry heavier loads without permanent deformation

Increased fatigue resistance, enabling the system to endure high duty cycles over several years

Excellent wear and corrosion resistance, ensuring performance in dusty, humid, or chemically active environments

With these material advantages, KASIN’s chains maintain structural integrity even after millions of operating cycles.

2. Dual-Axle Chain Construction

Many traditional chain systems use single-pin designs, which concentrate load forces in narrow areas, accelerating fatigue. In contrast, KASIN implements a dual-axle chain configuration, which:

Distributes mechanical stress more evenly across the link assembly

Reduces the risk of chain elongation and link cracking

Enhances load stability, particularly around bends and inclines

This robust construction ensures that even under continuous operation and dynamic load conditions, the chain maintains its geometry and alignment over time.

3. Integrated Self-Lubrication

To address one of the most common causes of mechanical failure—inconsistent or inadequate lubrication—KASIN integrates self-lubricating technology into its chain systems. This design innovation includes:

Embedded oil reservoirs that release lubricant gradually during operation

Low-friction materials at contact surfaces that reduce wear

Sealed bearing elements that prevent dust or debris contamination

With this system in place, the need for manual lubrication is drastically reduced, minimizing labor costs and improving reliability.

4. Designed to Withstand High-Temperature Environments

Manufacturing environments such as powder coating lines, paint shops, and heat-treatment zones subject conveyor systems to extreme temperatures. KASIN designs its overhead chain conveyors to perform optimally at up to 400°C, thanks to:

Heat-treated steel components that retain shape and strength under thermal expansion

Heat-insulated chain guides and brackets

Precision assembly tolerances that account for thermal shifts

This makes KASIN conveyors ideal for harsh thermal environments where other systems would degrade rapidly or fail altogether.

Cost Comparison: Durable vs. Conventional Conveyor Systems

Let’s look at the cost implications of choosing a high-durability overhead chain conveyor from KASIN compared to a conventional system.

Factor | Conventional System | KASIN Durable System |

Initial Investment | Lower | Slightly Higher |

Estimated Lifespan | 1–2 years | 3–5 years |

Annual Maintenance Costs | High | Low |

Downtime Frequency | Frequent | Minimal |

Parts Replacement Rate | High | Low |

ROI After 3 Years | Moderate | High |

The slightly higher upfront investment in a KASIN system pays off significantly over time by reducing maintenance and replacement costs, increasing uptime, and enhancing overall production efficiency.

Conclusion: Durability is a Strategic Investment

When it comes to selecting an overhead chain conveyor, focusing solely on upfront costs is a short-sighted approach. What truly matters is how the system performs over time—how often it fails, how much it costs to repair, and how it supports your production goals.

By choosing a durable conveyor solution from KASIN, you’re not just buying equipment. You’re investing in:

Greater production uptime

Lower maintenance and repair costs

Safer and more stable operations

Long-term operational excellence

KASIN Industries (Shanghai) Co., Ltd. has built its reputation on delivering high-durability, low-maintenance conveyor systems that serve real-world manufacturers across the globe. Their overhead chain conveyors are trusted in demanding environments because they’re engineered to last, perform, and reduce total operational risk.